2024-07-26

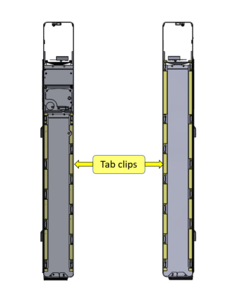

Reattaching Tab Clips

Required Tools:

- 3M multiple ratio two-part applicator

- 3M scotch-weld epoxy adhesive DP-420

- 3M scotch-weld applicator tip

- 2:1 ratio applicator

- Scrap cardboard

- Safety glasses

- IPA wipes

- Masking / painter's tape

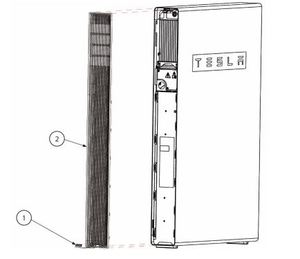

- Remove the side panel from Powerwall to expose the radiator by gently pressing at 1 and 2 before pulling from the bottom.

- Identify where the tab clip was previously attached to the component, based on existing residue and reference photos.

- Using IPA wipes, wipe down the surfaces in and around all sealant locations. Ensure any oils, residue, remnants of prior sealant, and other surface contaminants are removed.

- Prepare for sealant application by attaching the front face of the tab clip onto the back face of the cover. Ensure all tab clip holes line up with the cover.

- Cut 6 strips of masking tape 8" (20 cm) long and pre-attach one end of each along the height of the Powerwall.

- Prepare the applicator gun by disengaging the locking tab, inserting the plunger through the front, sliding in the Duo-Pak, and securing the locking tab.

- Remove the twist cap on the cartridge end and expel sealant on a scrap piece of cardboard. Ensure both channels are being dispensed.

- Secure the cartridge end with an applicator tip, rotating it 90 degrees to lock into place.

-

Squeeze the applicator gun's trigger until uniformly mixed sealant is dispensed

in a 2:1 ratio.

NoteThe sealant mix ratio is 2:1 and provides 20 minutes of work-life, allowing time to adjust for the desired fit prior to curing.

- Apply a thin layer of sealant along the back face of the tab clip.

- Firmly press the side panel and tab clip together onto the Powerwall and hold in place for 30 seconds.

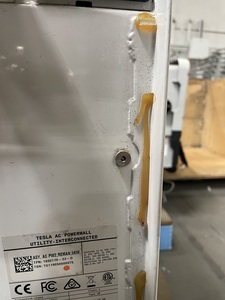

- Fully attach the masking tape to maintain pressure and hold the tab clip in place during curing. Add additional tape as needed, especially around key features or bulging areas. Ensure that the cover is flush with the Powerwall and that the masking tape is not touching any sealant before it hardens.

- Communicate to the customer that the sealant will take 24 hours to fully cure at 72 F (22 C). Instruct them to remove the masking tape after this duration.

- Using IPA wipes, wipe down the surfaces in and around all sealant locations. Ensure any oils, residue, remnants of prior sealant, and other surface contaminants are removed.