Make Powerwall 3 Wiring Connections

Make Powerwall 3 AC Power Connections

Connect Powerwall 3 to the appropriate breaker size

depending on the desired power / current output (configured in Tesla One):

| Maximum Continuous Current | Power Output (AC) | Breaker (Overcurrent Protection) |

|---|---|---|

48 A On-grid | 11.5 kW On-grid | 80 A* |

| 48 A | 11.5 kW (default) | 60 A |

| 41.7 A | 10 kW | 60 A |

| 31.7 A | 7.6 kW | 40 A |

| 24 A | 5.8 kW | 30 A |

*Powerwall 3 can only provide 15.4 kW when off-grid and when there is sufficient solar; when the system is on-grid, and/or when solar production is insufficient, Powerwall 3 will provide 11.5 kW. If enabling this feature, Powerwall 3 must be installed with an 80 A breaker and appropriately sized conductors.

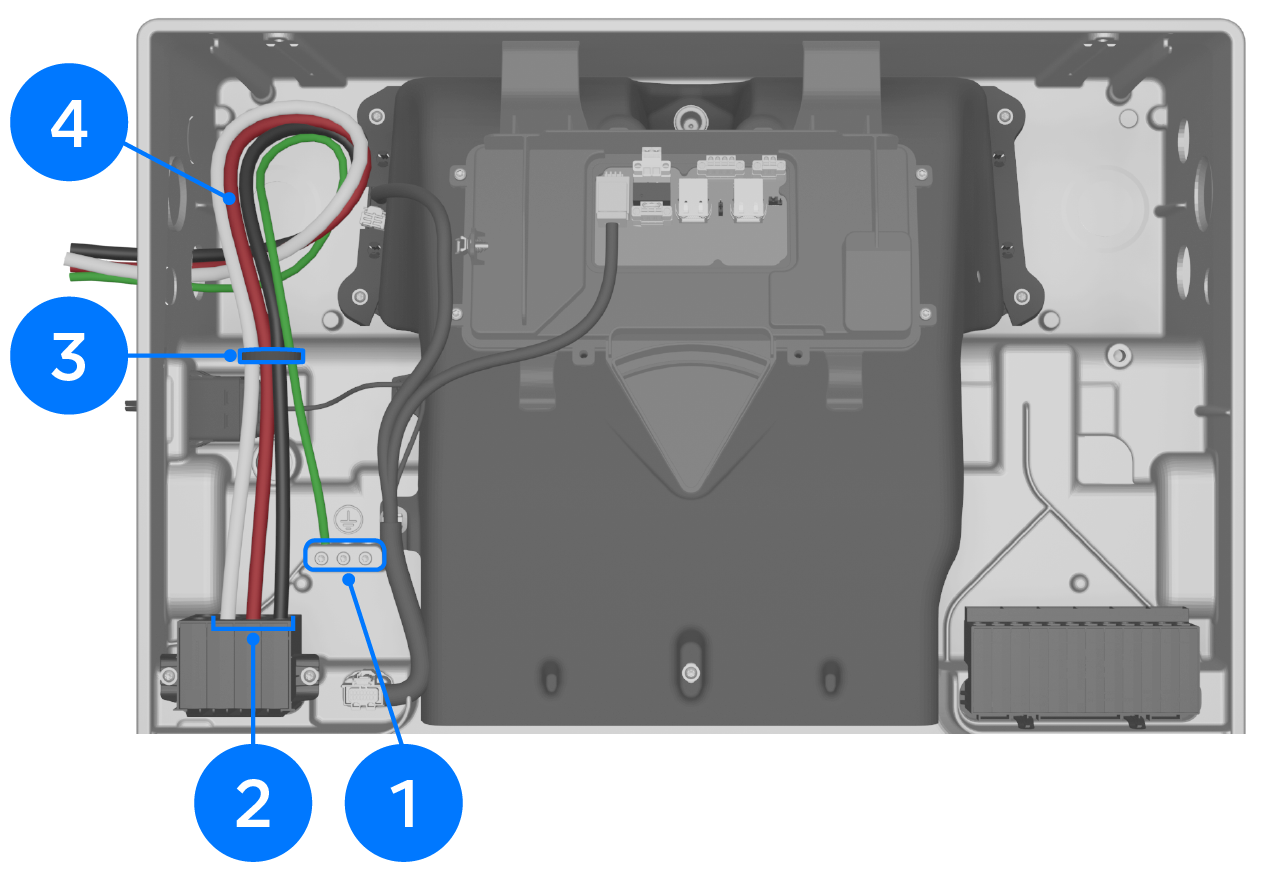

| 1 | Ground terminals: 12-4 AWG (4-25 mm2), torque to 35 in-lb with Torx T20 |

| 2 | N / L2 / L1: 10-4 AWG (6-25 mm2), use up to 4.5 mm (3/16 inch) cabinet / electronics tip screwdriver |

| 3 | Gather conductors in provided cable tie |

| 4 | Leave a service loop |

CAUTION

If using a fuse

as the Powerwall 3 overcurrent protection

device, it must be a Class RK1 Fast Acting fuse. Use one of the following fuses

or equivalent:

| Fuse Type | Manufacturer | Part Number |

|---|---|---|

| 80 A Fast-Acting Fuse, Class RK1, >= 250VAC, CLF | Littelfuse | KLNR080 |

| Eaton / Bussmann | KTN-R-80 | |

| Mersen / Ferraz Shawmut | A2K80R | |

| 60 A Fast-Acting Fuse, Class RK1, >= 250VAC, CLF | Littelfuse | KLNR60 |

| Eaton / Bussmann | KTN-R-60 | |

| Mersen / Ferraz Shawmut | A2K60R | |

| 40 A Fast-Acting Fuse, Class RK1, >= 250VAC, CLF | Littelfuse | KLNR40 |

| Eaton / Bussmann | KTN-R-40 | |

| Mersen / Ferraz Shawmut | A2K40R | |

| 30 A Fast-Acting Fuse, Class RK1, >= 250VAC, CLF | Littelfuse | KLNR30 |

| Eaton / Bussmann | KTN-R-30 | |

| Mersen / Ferraz Shawmut | A2K350 |

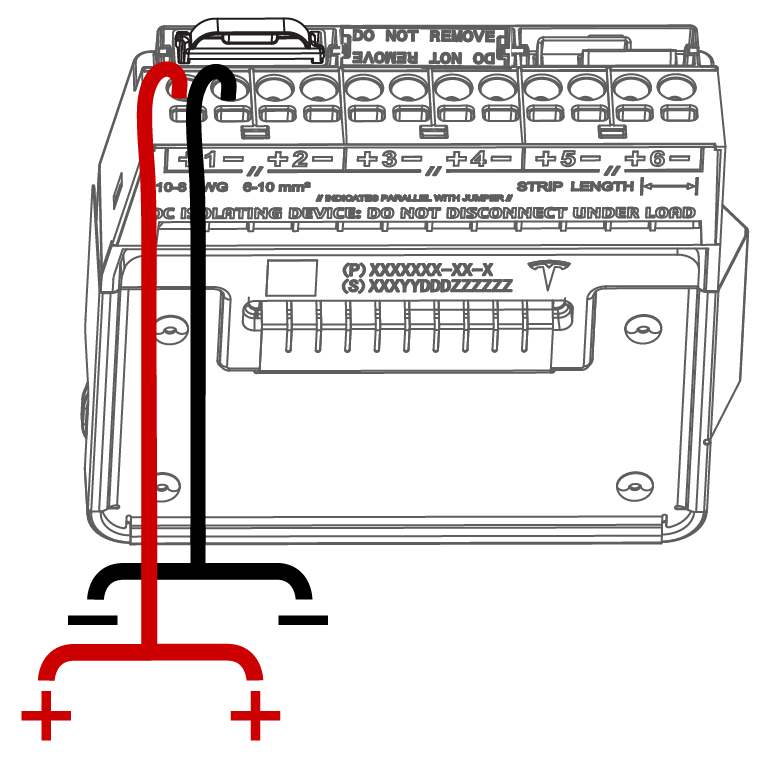

Make Powerwall 3 PV Power Connections

Warning

Turn the Powerwall 3 Enable switch OFF before doing any wiring.

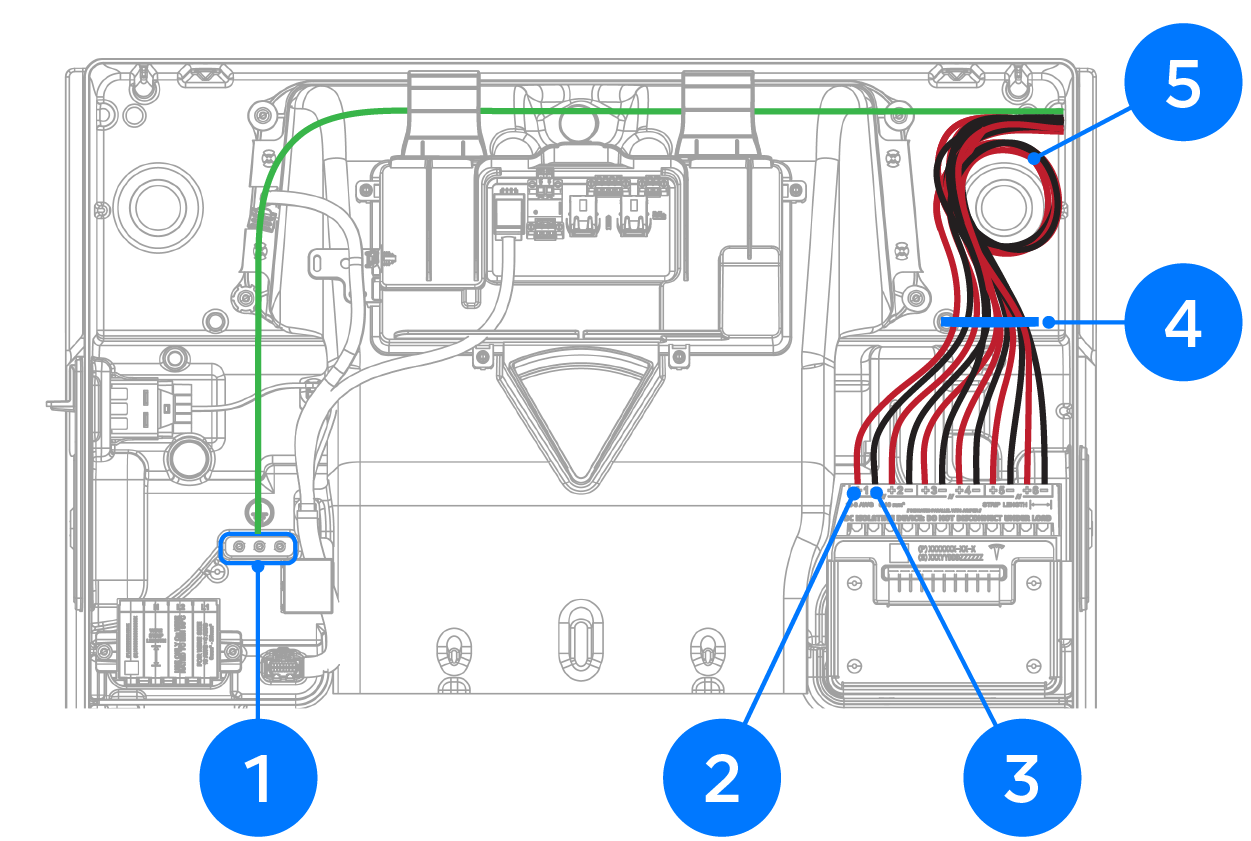

| 1 | Ground terminals: 12-4 AWG (4-25 mm2), torque to 35 in-lb with Torx T20 | |

| 2 | MPPT Positive PV inputs: 10-6 AWG (6-16 mm2) | Use up to 4.5 mm (3/16 inch) cabinet / electronics tip screwdriver |

| 3 | MPPT Negative PV inputs: 10-6 AWG (6-16 mm2) | |

| 4 | Gather conductors in provided cable tie | |

| 5 | Leave a service loop | |

Important Notes on Installing MPPT

Jumpers:

- The jumpers provided in the Powerwall 3 accessory bag can only be used with the Powerwall 3 model they shipped with:

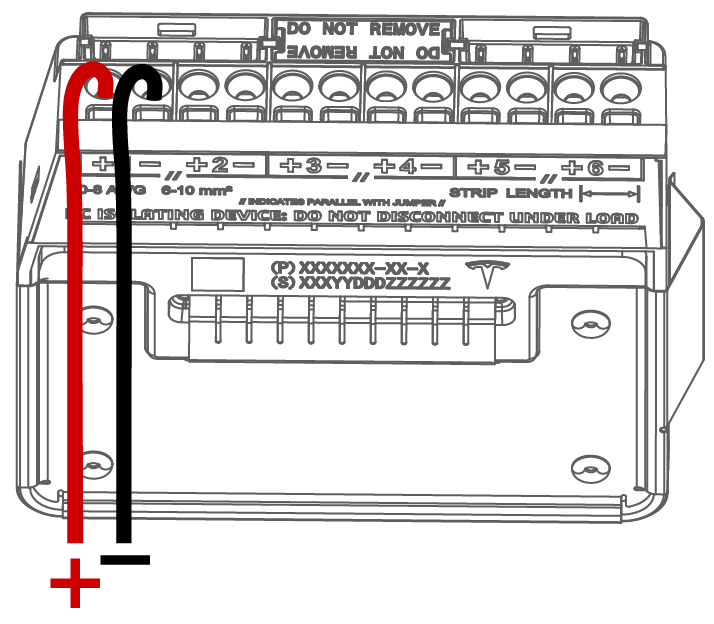

- Jumpers can be used when IMP > 13A. Use jumpers to allow a single MPPT to intake strings with a total IMP up to 26A

- Land the combined circuit (2

strings in parallel = 1 circuit) or string with IMP greater than 13A

in the terminal and connect the jumper from:

- MPPT 1 to MPPT 2

- MPPT 5 to MPPT 6

- MPPT PV inputs 3 and 4 cannot be combined and are closed from the factory

- Do not use jumpers on Solar Roof jobs - you cannot parallel more than two strings so combined circuit IMP will always be less than 13A DC

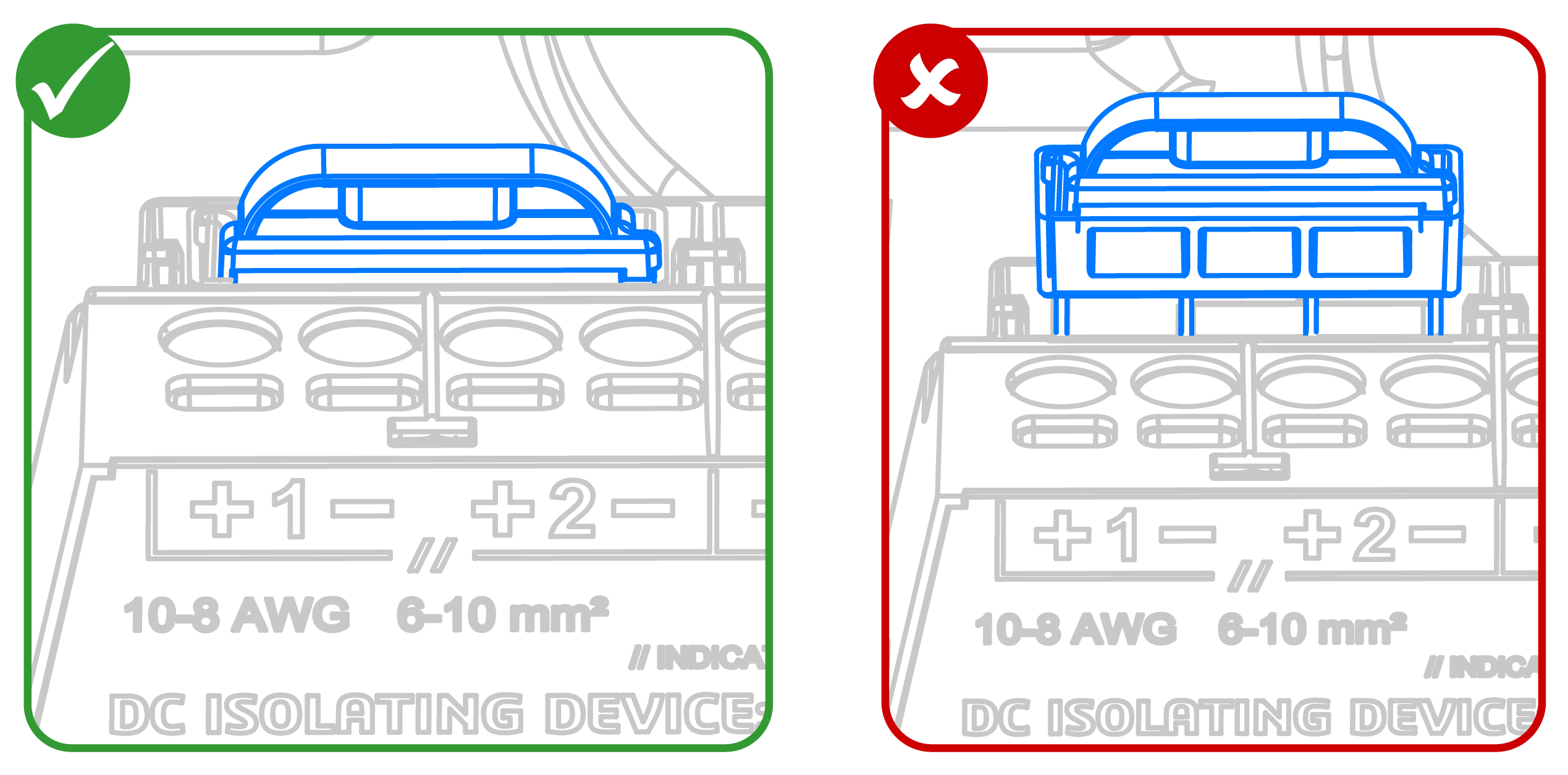

- Ensure each jumper is fully

seated in the connector!

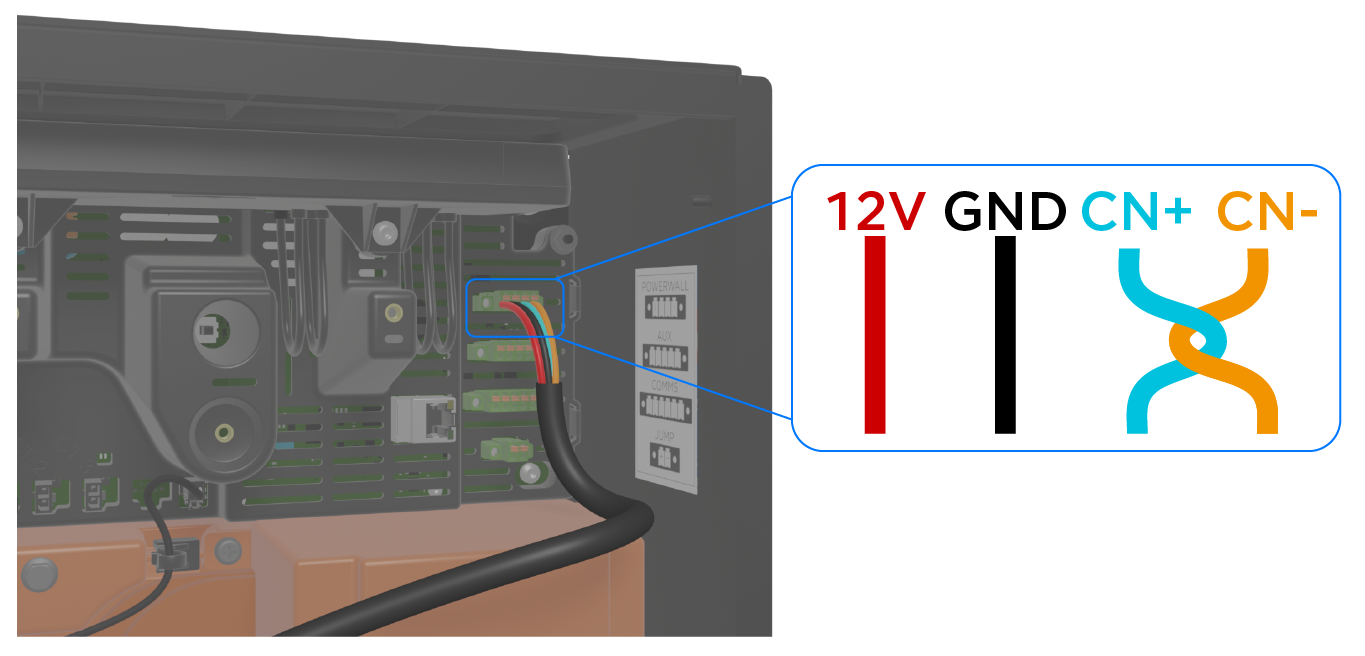

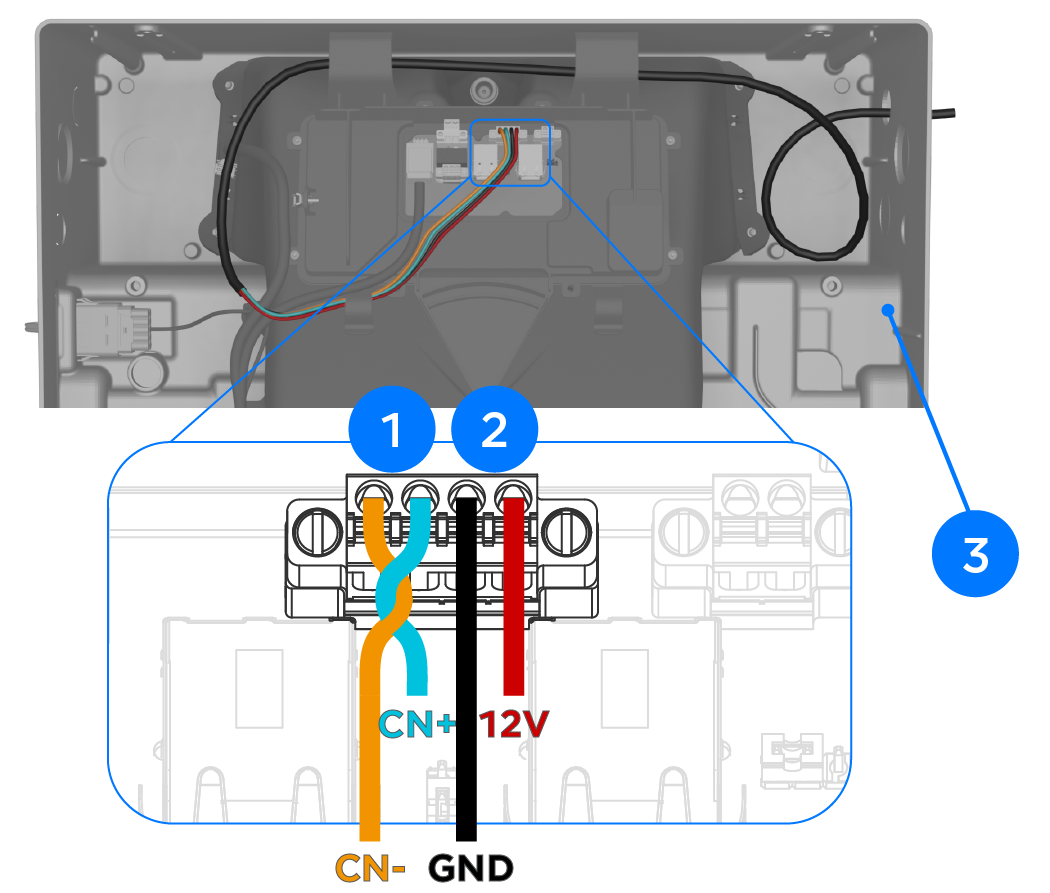

Connect Powerwall 3 to the Backup Switch / Backup Gateway 2 / Gateway 3

| 1 | CN- (CAN LO): 24-16 AWG (0.2-1.5 mm2) | Use up to 3 mm (3/32 inch) cabinet / electronics tip screwdriver |

| CN+ (CAN HI): 24-16 AWG (0.2-1.5 mm2) | ||

| 2 | GND: 24-16 AWG (0.2-1.5 mm2)* | |

| 12V+: 24-16 AWG (0.2-1.5 mm2)* | ||

| 3 | Leave a service loop | |

*18 AWG is the recommended minimum wire gauge due to potential voltage drop on long wire runs.

Note

CN- and CN+ must be twisted pair.

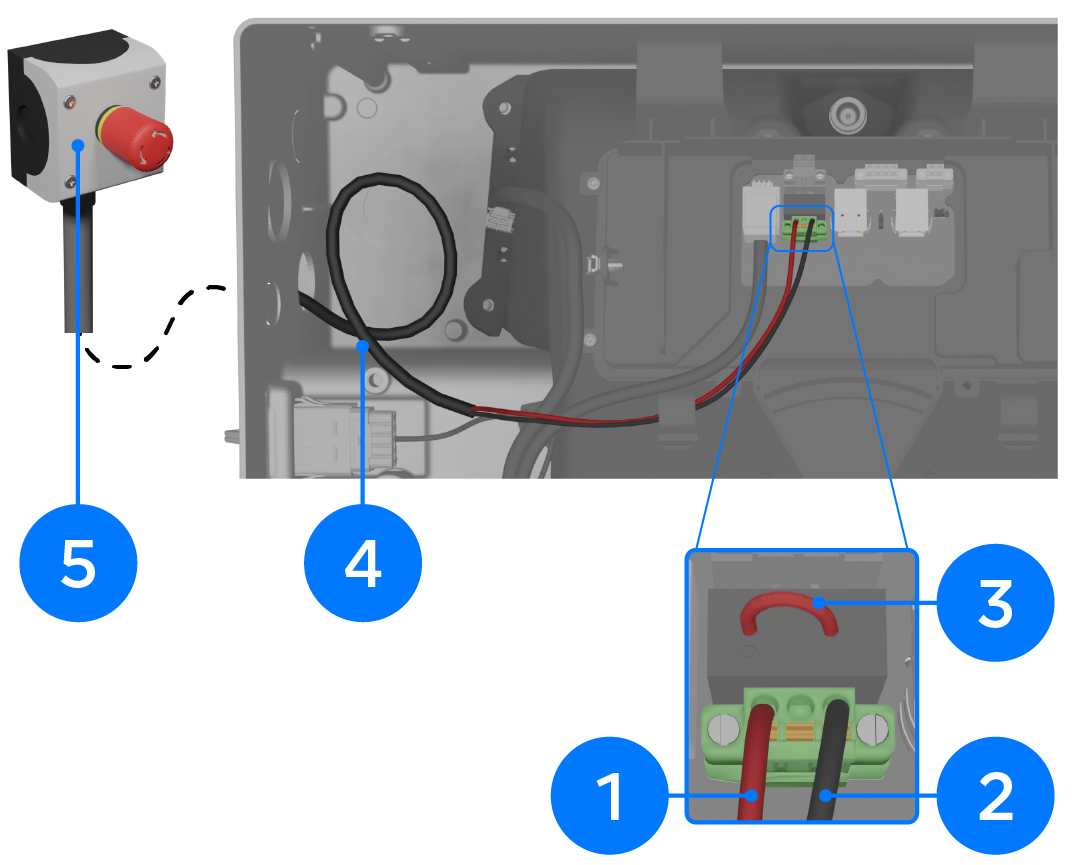

Install System Shutdown Switch Where Required

CAUTION

The System Shutdown

Switch must be connected to Powerwall 3. Do not connect it to the

Backup Gateway 2 as it will not work.

| 1 | Rapid Shutdown IN: 24-16 AWG (0.2-1.5 mm2) | Use up to 3 mm (3/32 inch) cabinet / electronics tip screwdriver |

| 2 | Rapid Shutdown OUT: 24-16 AWG (0.2-1.5 mm2) | |

| 3 | Remove RSD jumper when installing System Shutdown Switch; otherwise, leave installed | |

| 4 | Leave a service loop | |

| 5 | Connect the RSD wiring to a suitable DC switch (see the Powerwall 3 with Backup Gateway 2, Backup Switch, or Gateway 3 installation manual for full details) | |

Note

See Multi-Powerwall 3 Installations for

instructions to connect multiple Powerwall 3 units to a System Shutdown Switch.

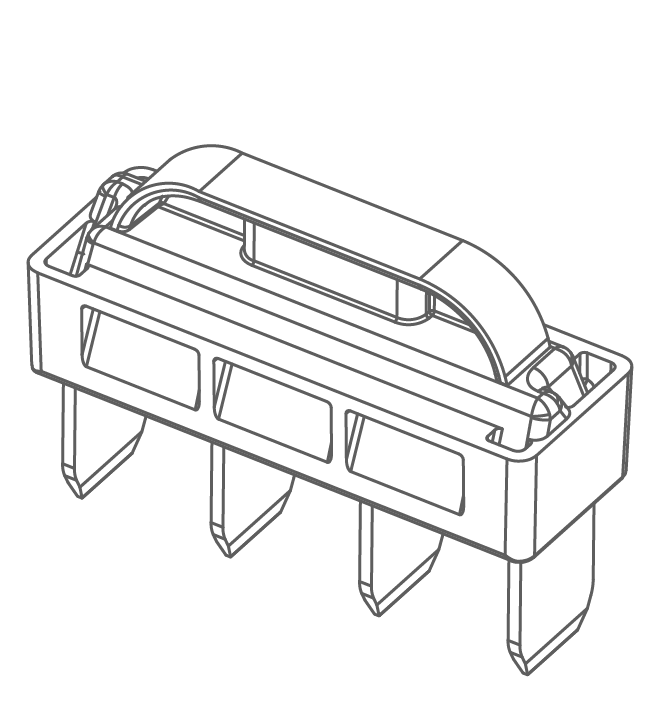

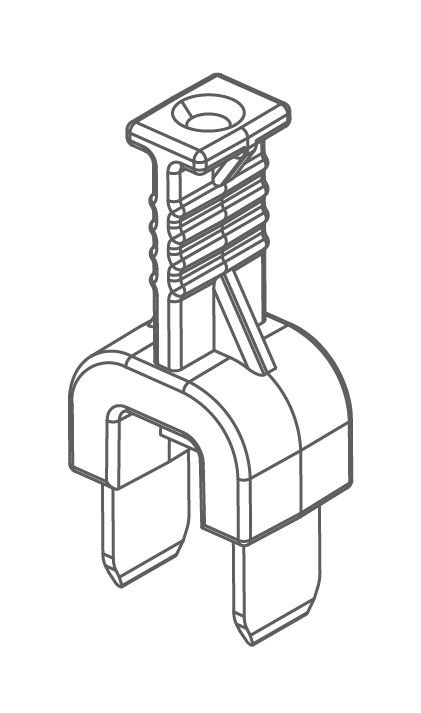

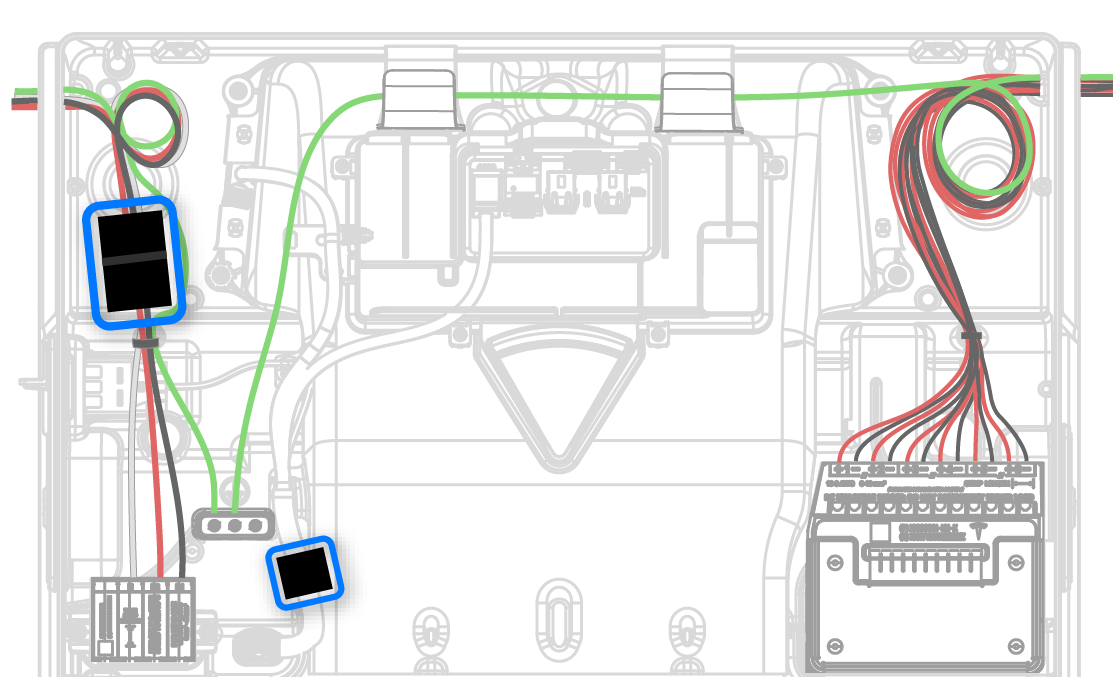

Install Ferrite Cores

- (1) large clamp-on ferrite core for the AC conductors

- (1) small clamp-on ferrite core for the TACO low voltage harness

CAUTION

Ferrite cores

are fragile; handle with caution.

Note

Ground wires do not need to be

included in the ferrite cores.

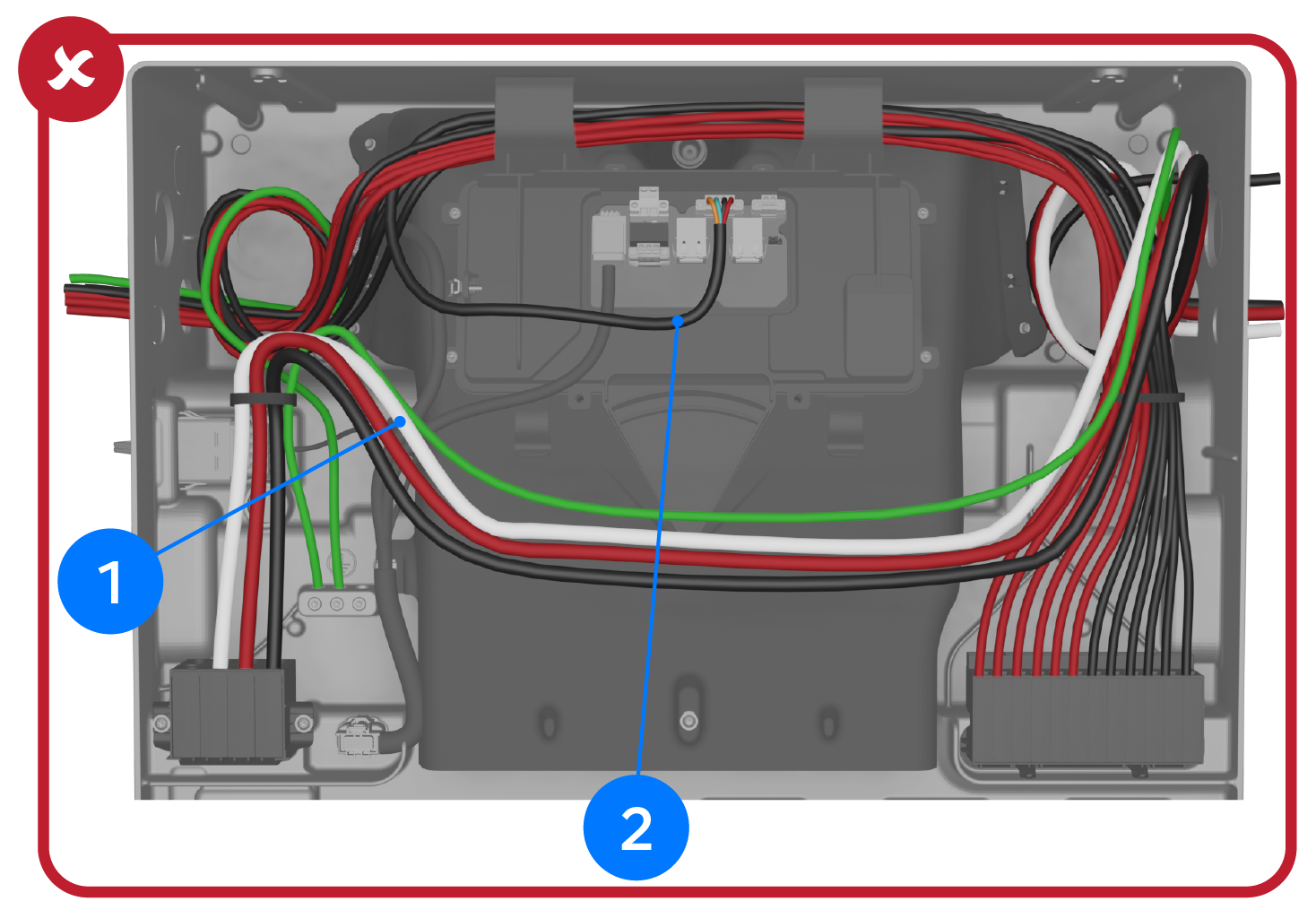

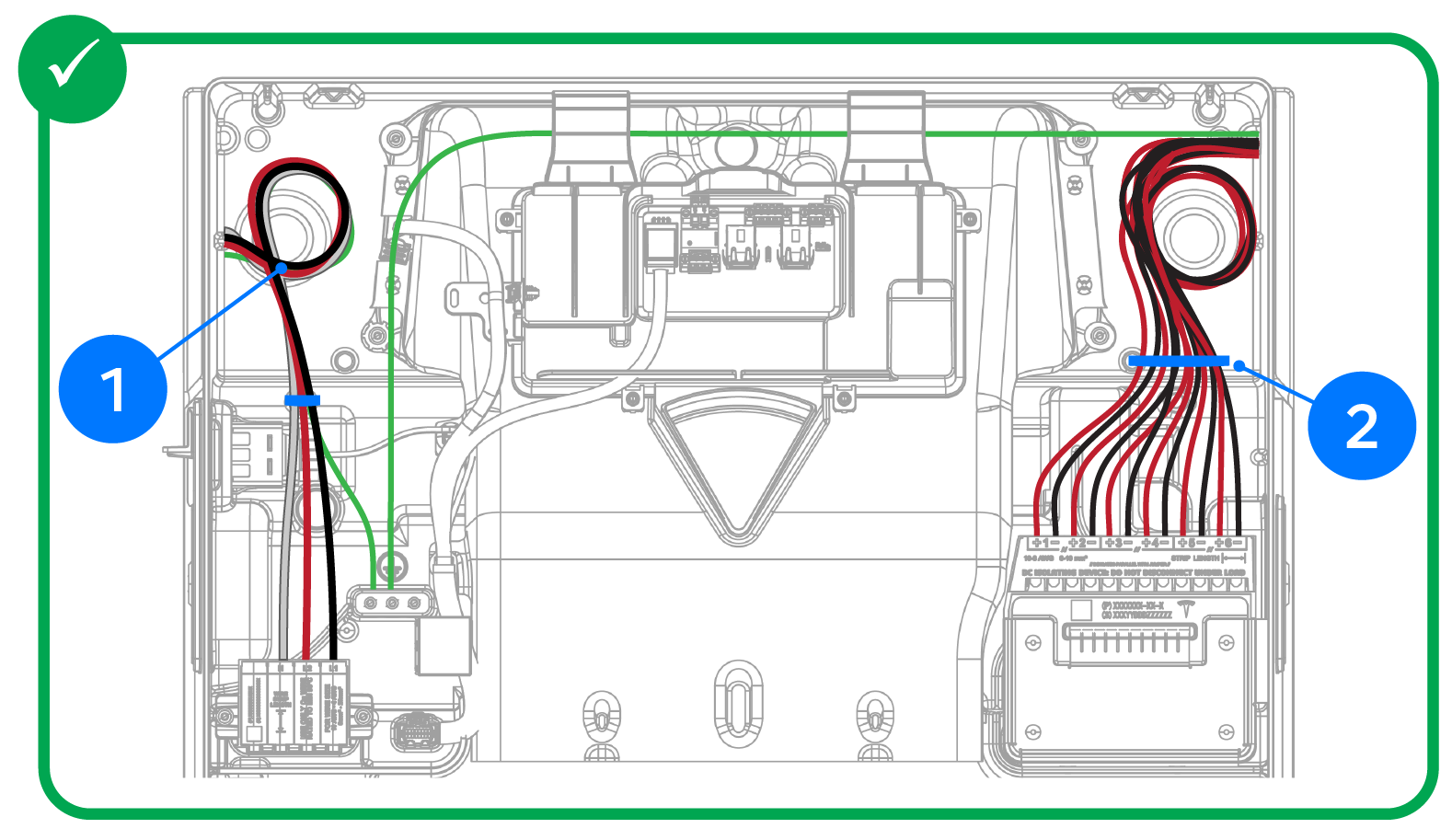

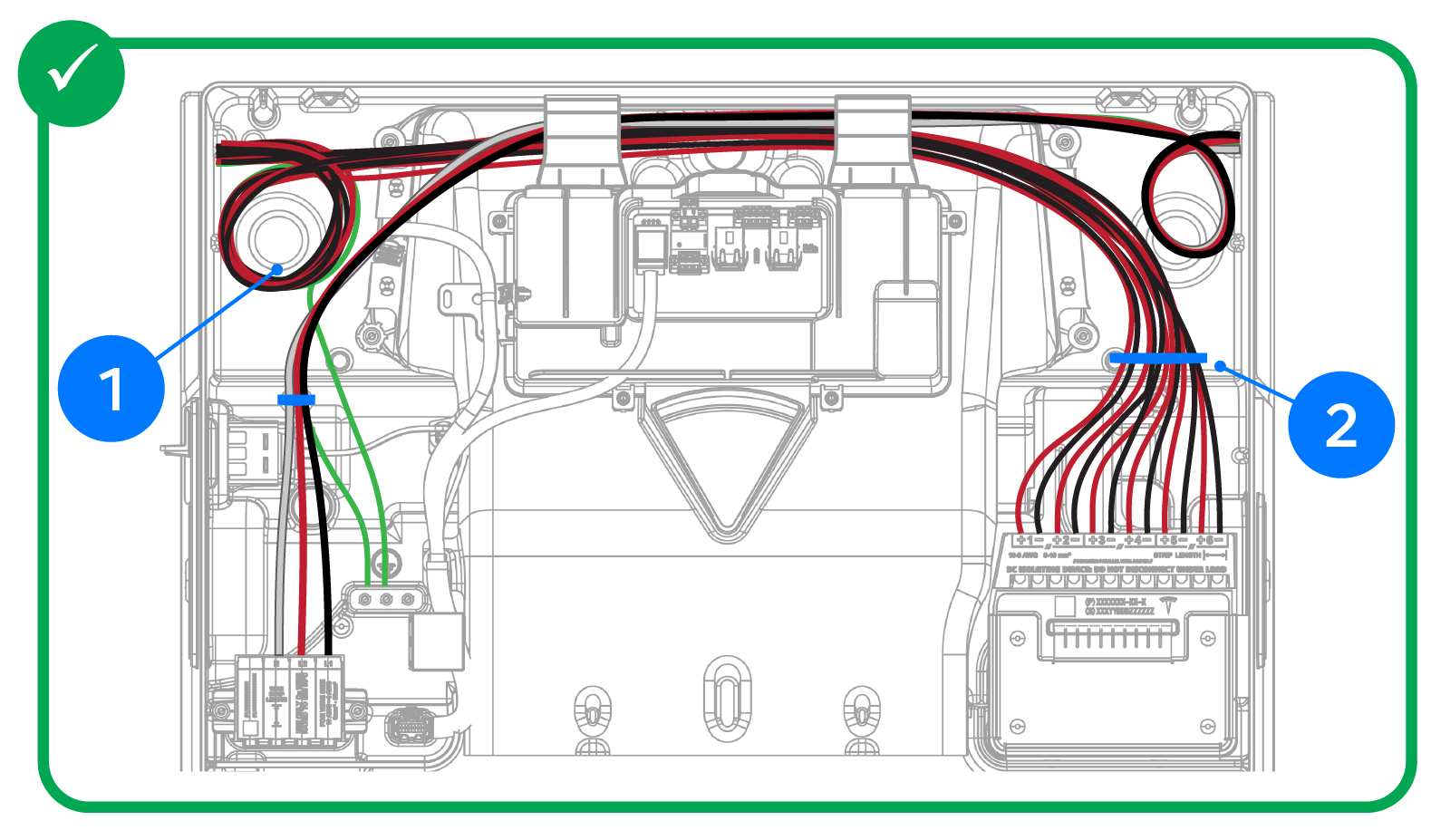

Important Notes on Wire Routing

| 1 |

|

| 2 |

|

| 1 |

|

| 2 |

|