Install Mid-Circuit Interrupters in PV Array

MCI Locations - Rapid Shutdown Applications

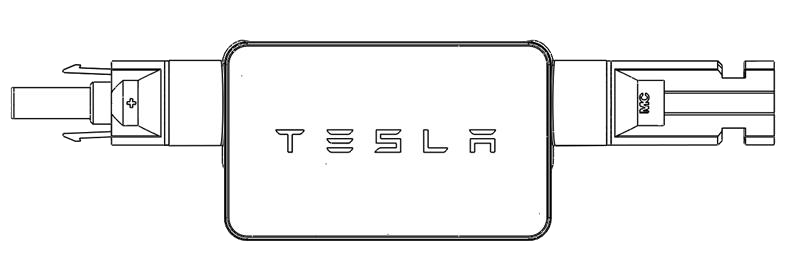

The Tesla Mid-Circuit Interrupter (MCI) is used within PV strings and arrays to meet the Rapid Shutdown requirements of NEC Article 690.12. For information on how the Tesla MCI functions with Powerwall 3 as a Photovoltaic Rapid Shutdown System (PVRSS), see Appendix D: Solar Rapid Shutdown.

The quantity and placement of MCIs necessary to meet Rapid Shutdown requirements in NEC Article 690.12 (B) and Canadian Electrical Code (CE Code), C22.1, is governed by the UL 3741 (PV Hazard Control System or PVHCS) listing applicable to various array types. Refer to the UL 3741 Application Addendum for a complete list of systems in the US and Canada that have been certified to UL 3741 when installed together with Powerwall 3 and Tesla MCI. Always refer to the applicable PVHCS datasheets and references included in the addendum for detailed instructions to ensure adequate compliance and safe operation.

MCI Locations - Where Rapid Shutdown Not Required

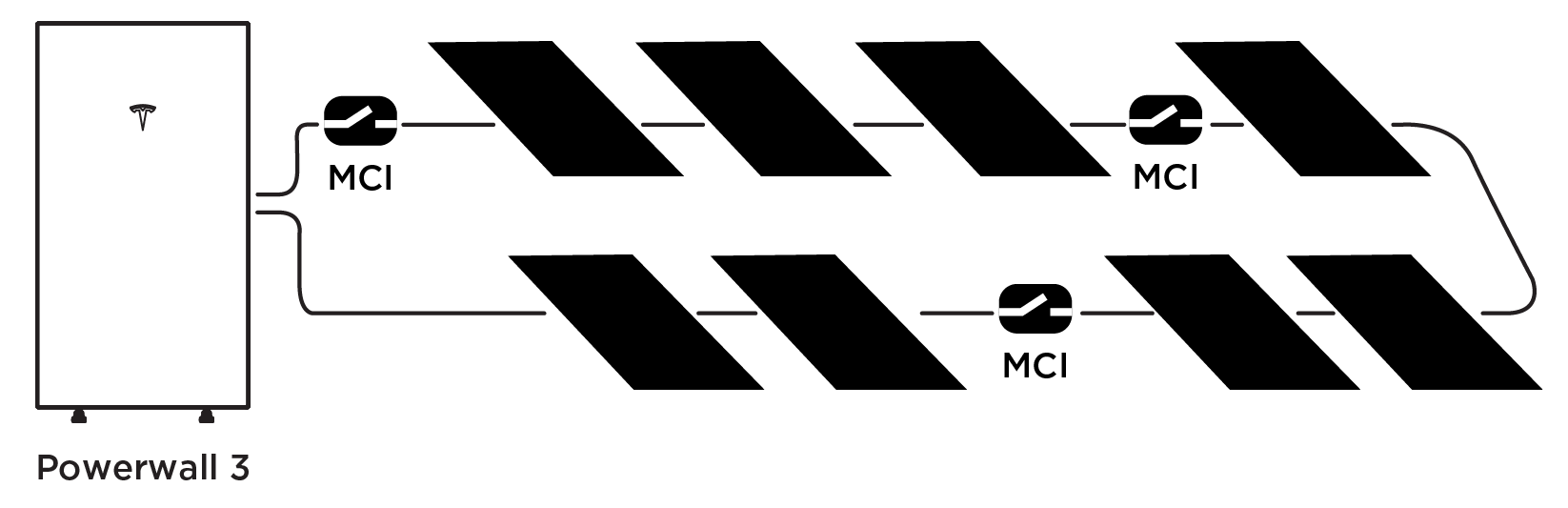

MCIs must still be installed on each PV string in systems that are not subject to the requirements of NEC Article 690.12, such as ground-mount and carport arrays.

- The 165V inside-the-array listing (also referred to as the (1) MCI per (3) modules rule) can be applied (see MCI Locations - Rapid Shutdown Applications for an example diagram)

- The "Always 4" rule can be

applied:NoteThis rule was created for simplicity. Strings with a low module count may also use the 165V inside-the-array PVHCS listing noted above.NoteMCI-2s are not allowed to be plugged directly into each other due to risk of damaging the connectors from rotating them.

Figure 3. Install (2) MCIs on each end of the string (for a total of (4) MCIs) Figure 4. String spans 2 arrays, install (1) MCI on each end of the string and (1) MCI on each end of the jumper (for a total of (4) MCIs)

For MCI-1, the Maximum Disconnect Voltage is 600 V, meaning (1) MCI per string is allowable.

Installation Best Practices

- Ensure that Tesla MCIs are not stored prior to installation in environments with moisture or dirt

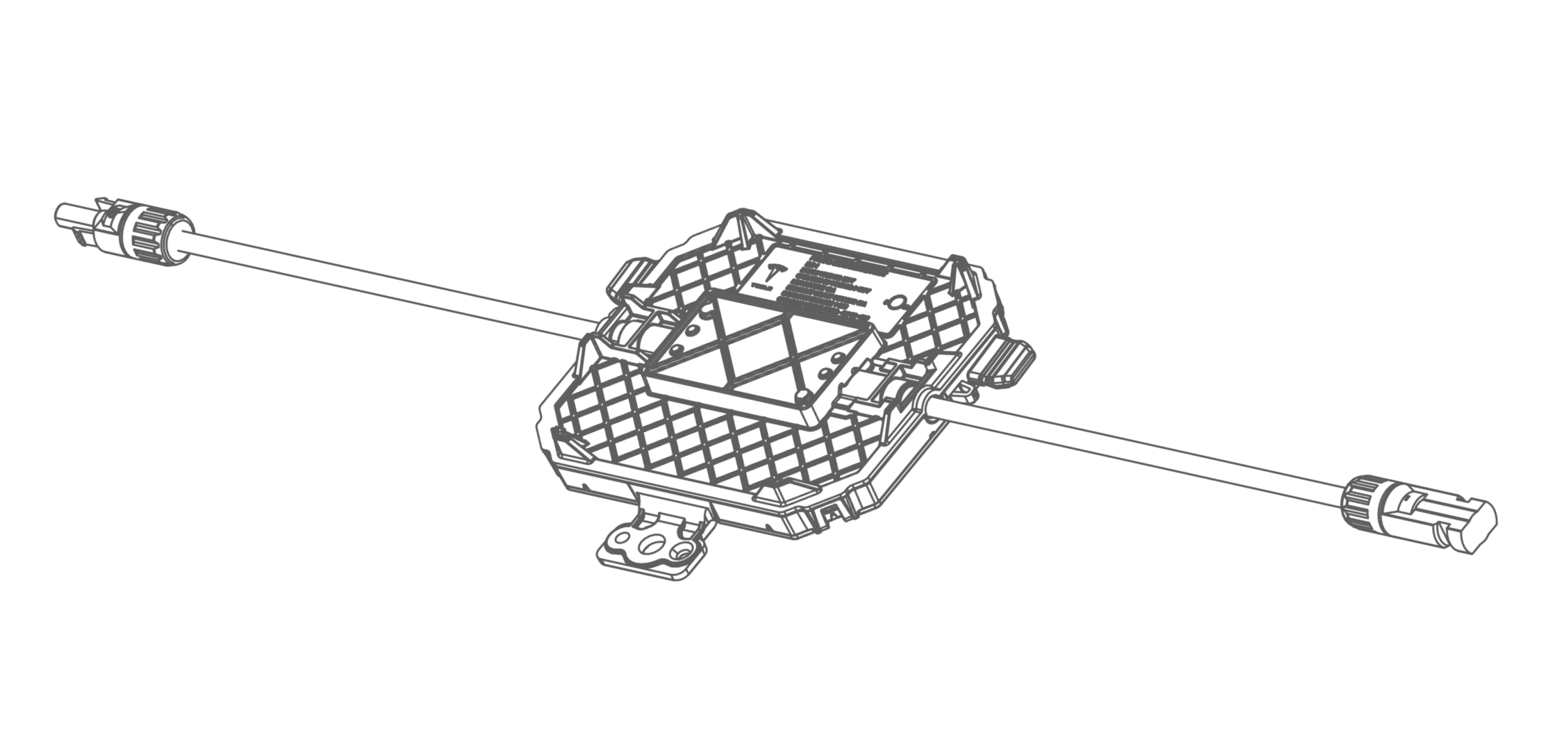

- Install the Tesla MCI in line with the PV modules using standard Staubli Type MC4 certified compatible connectors

- Ensure the MCI is minimum 12.7 mm (1/2 in) from glass or backside of a PV module

- For PV module installations, ensure the MCIs do not directly contact the roof. For Solar Roof installations, see the Solar Roof Installation Manual for proper mounting guidance

- For easier servicing of PV module installations, install the MCIs on the perimeter of the array if possible

- Always secure the MCI with appropriate wire management

- Ensure no more than 5 MCIs are connected per PV string

- Ensure that total DC circuit

length, from + MPPT terminal to - MPPT terminal (including module wire leads,

jumper wires and all wiring within the array boundary for any individual

string), does not exceed 160 m for single strings or

paralleled strings

- Total DC circuit length refers to the entire round trip wire length, from inverter to the roof, then back to the inverter

- Ensure paralleled strings are the same length, or as close in length as possible (if the paralleled strings are different lengths, it is likely the MCIs will not function properly; this likelihood increases the greater the difference in paralleled string lengths)

- Keep a completed string diagram indicating the layout of the array and the placement of each MCI (either a paper copy, electronic copy available in the field, or both)

Installing MCIs

- Connect the positive and negative

leads of the MCI to the corresponding positive / negative MC4 terminals of the

PV modules or solar roof modules.

- For PV module installations,

attach the MCI under the module frame.

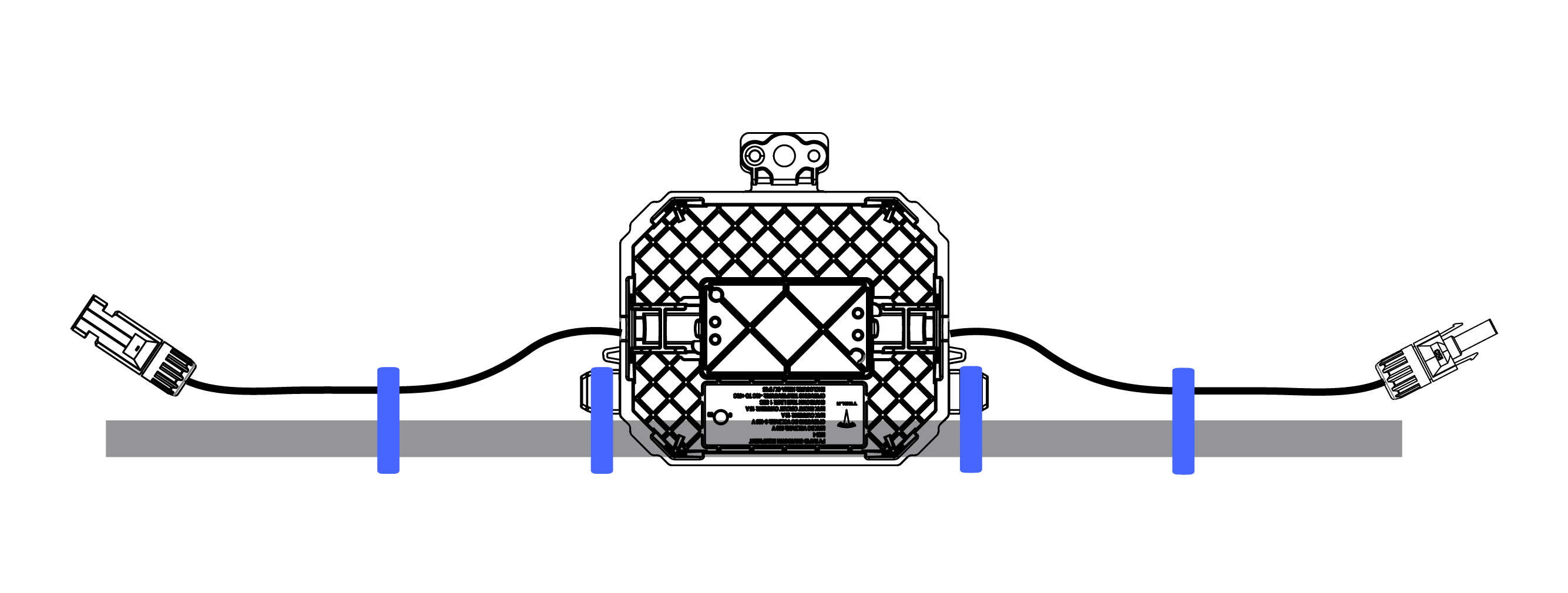

- To attach the MCI using

ZEP Home Run wire clips, install the (2X) clips to the module frame and

clip both ends of the MCI leads, then slot the MCI underneath the metal

frame.

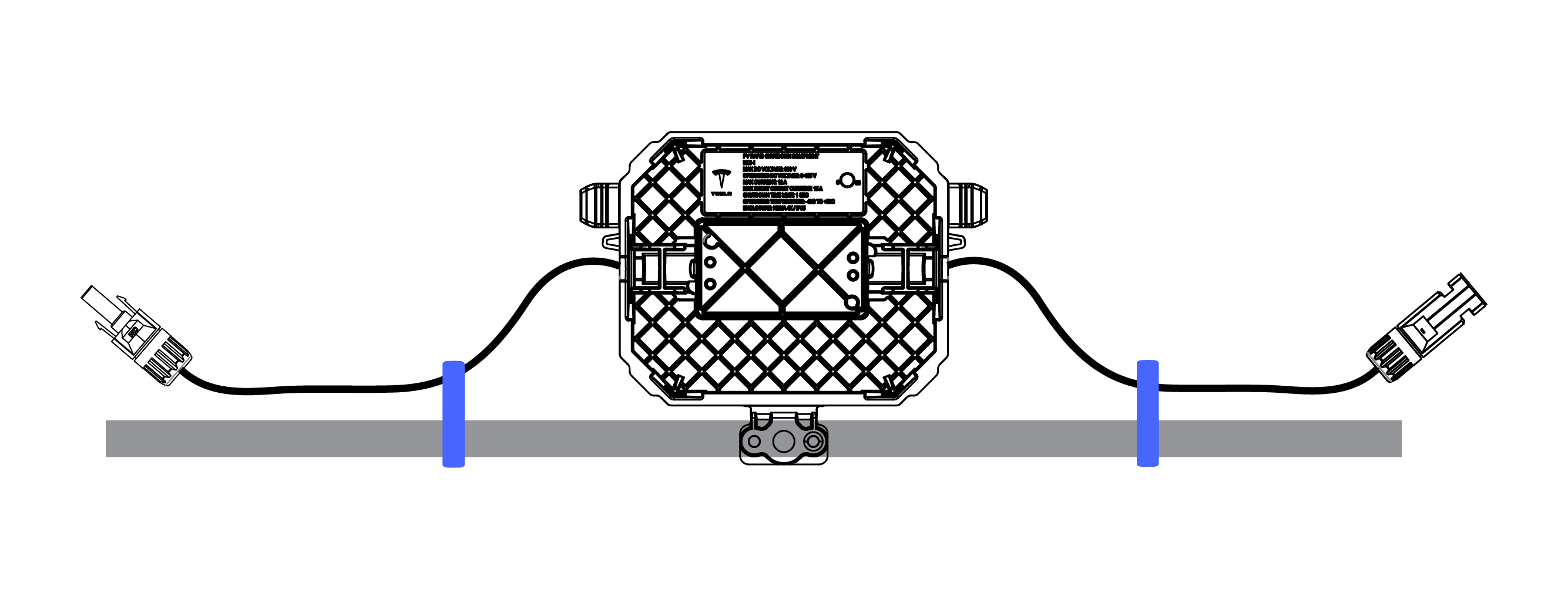

Figure 8. MCI-1 Attached with Wire Clips

Figure 9. MCI-2 Attached with Wire Clips NoteInstall the wire clips at least two inches from the end of the MC4 connector, but no more than six inches from the connector. Ensure the MCI is not directly contacting the roof.CAUTIONDo not twist the MC4 connectors on MCI-2. Twisting the connectors damages the electrical contacts inside, likely resulting in MCI failure. - To bolt the MCI to an

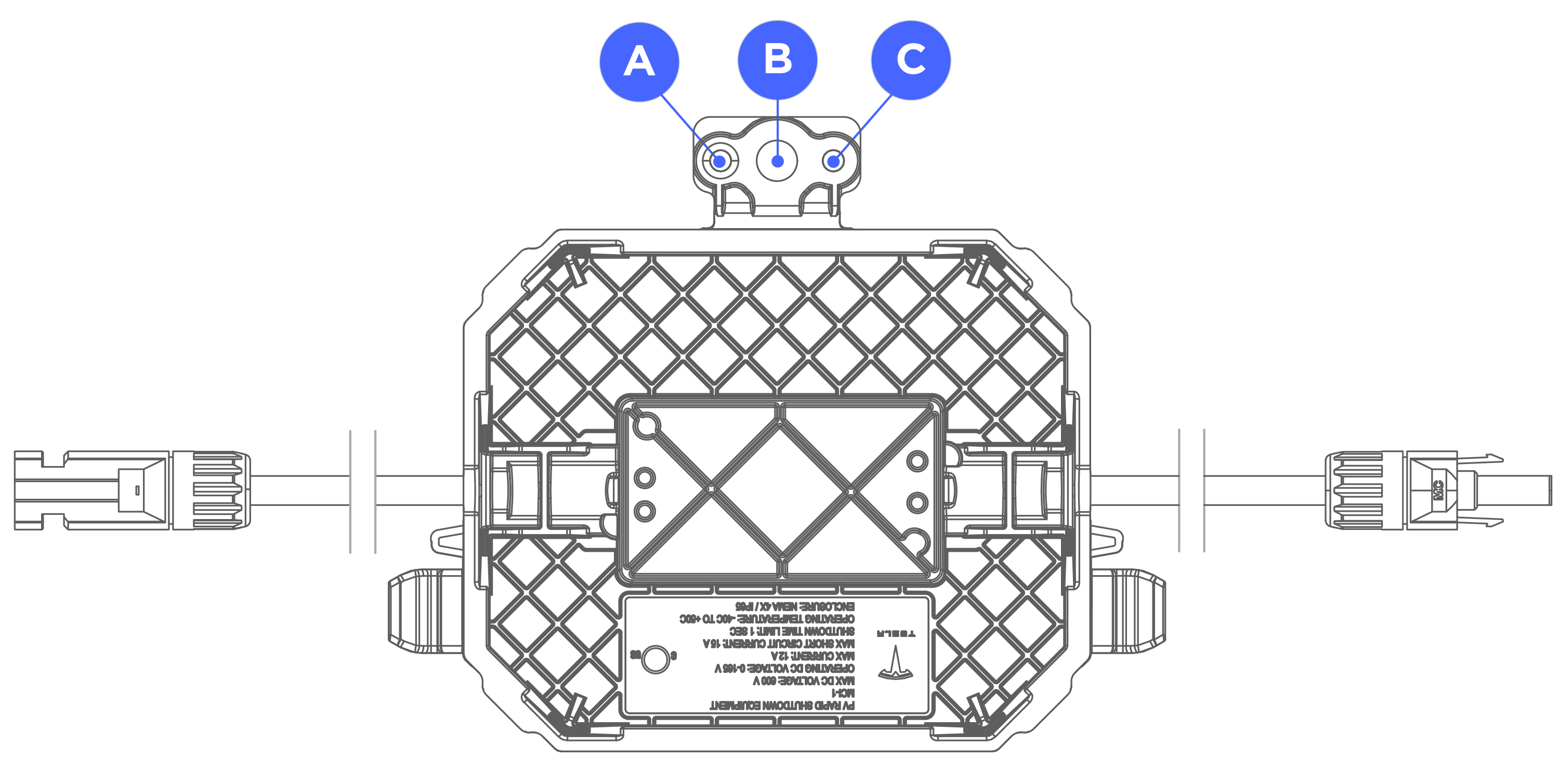

existing hole in the frame, align the MCI through hole with the frame

and use the appropriate mounting hardware as defined in MCI Mounting Hardware

Sizing .

NoteThis option is only available for MCI-1.

NoteThis option is only available for MCI-1.- Follow all module manufacturer’s instructions before mounting the MCI to the module frame. Ensure there is at least 0.5 in (13 mm) between the MCI and the module substrate, and only mount the MCI using existing holes in the module frame.

- For rail PV systems, use any of the mounting holes to mount the MCI directly to the rail (see MCI Mounting Hardware Sizing for mounting hardware sizes) or use the manufacturer’s module level power electronic mounting bracket and mount the MCI to the bracket.

- To attach the MCI using

ZEP Home Run wire clips, install the (2X) clips to the module frame and

clip both ends of the MCI leads, then slot the MCI underneath the metal

frame.

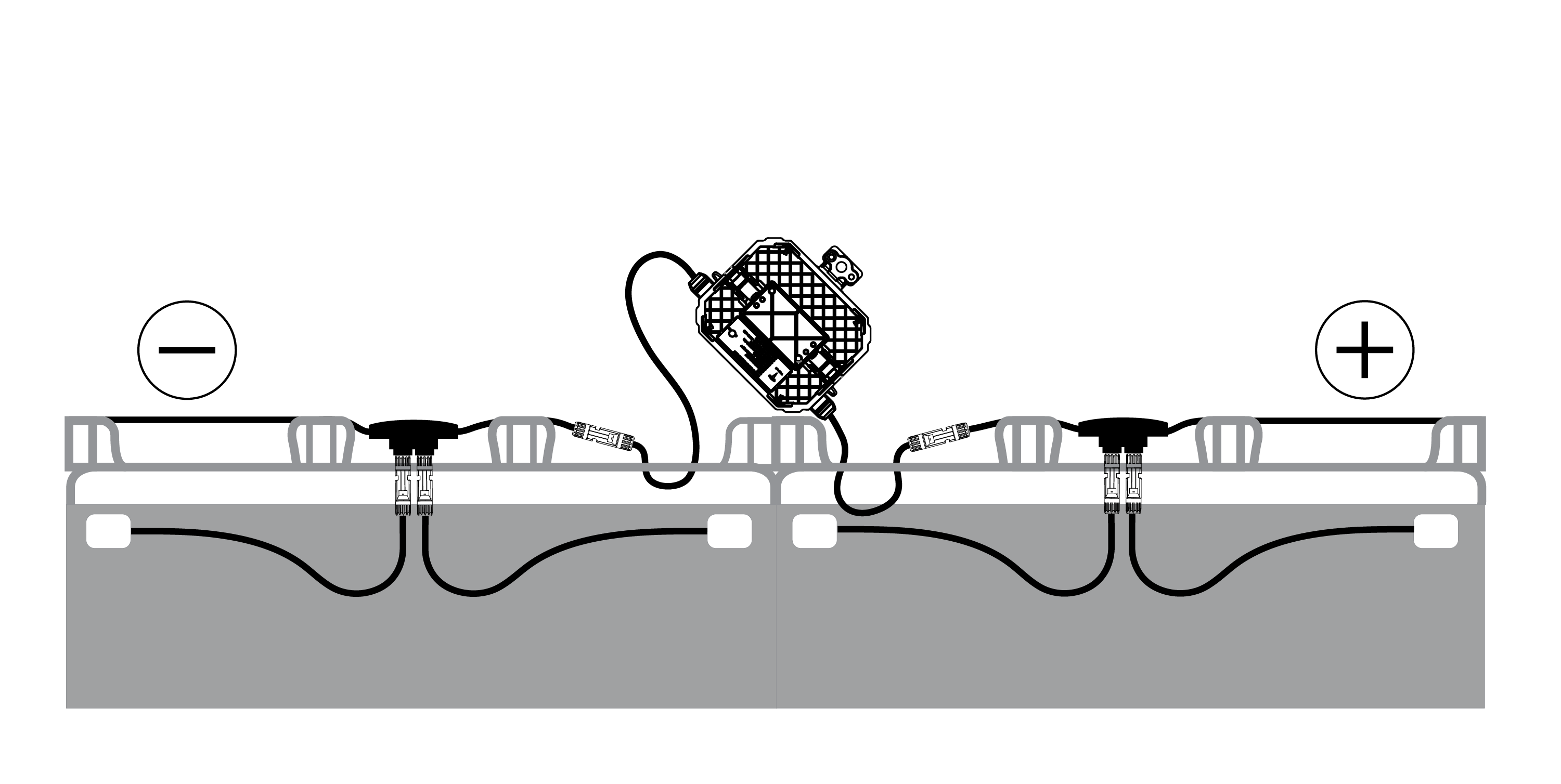

- To install MCI-1 on Solar Roof

installations, mount the MCIs directly to the roof, directly above the Tile

Footlaps and positioned at a slight angle as pictured below. Use the appropriate

mounting hardware as defined in the table below.

Figure 10. MCI-1 Installed with Solar Roof Tiles (V3 and earlier generations)

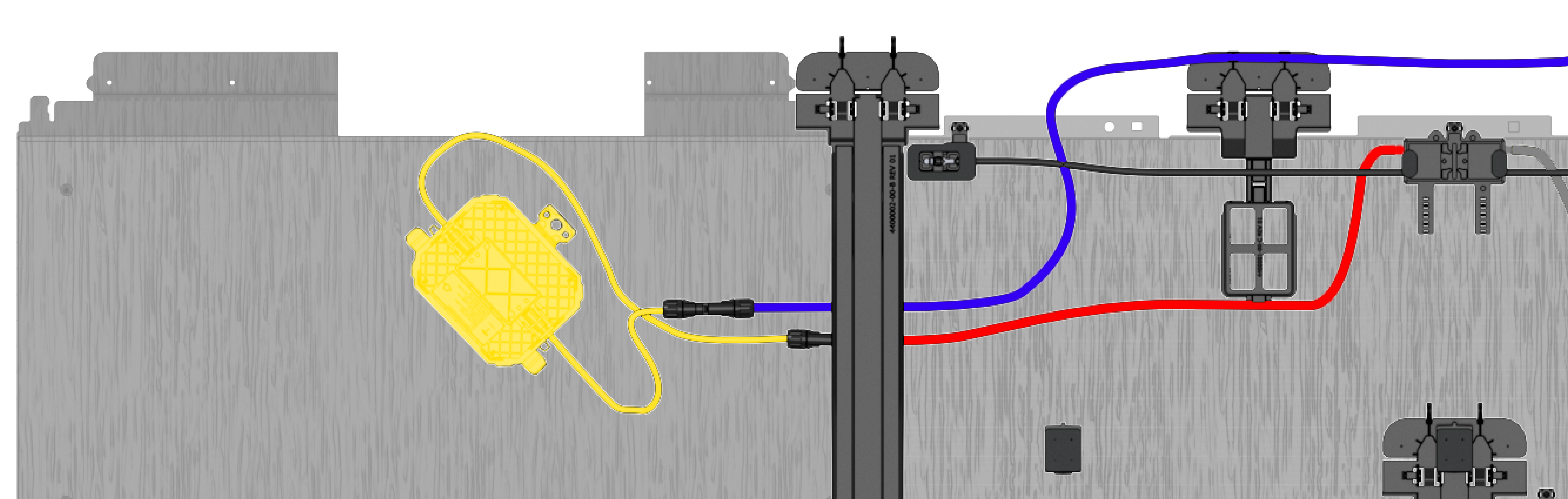

Figure 11. MCI-1 Installed on End of Solar Roof V3R String

Table 1. MCI Mounting Hardware Sizing Through Hole Hardware A Wood Screw (No. 8) Screw (up to M4 (5/32")) B Bolt (up to M8 (5/16")) C Nail (8D) Screw (up to M4 (5/32")) - To install MCI-2 on Solar Roof

installations, attach each lead of the MCI to the corresponding Staubli MC4

connector, and place an MC4 cap on each of the remaining MC4 connectors. Secure

the cables in the wire management clips. CAUTIONDo not twist the MC4 connectors on MCI-2. Twisting the connectors damages the electrical contacts inside, likely resulting in MCI failure.