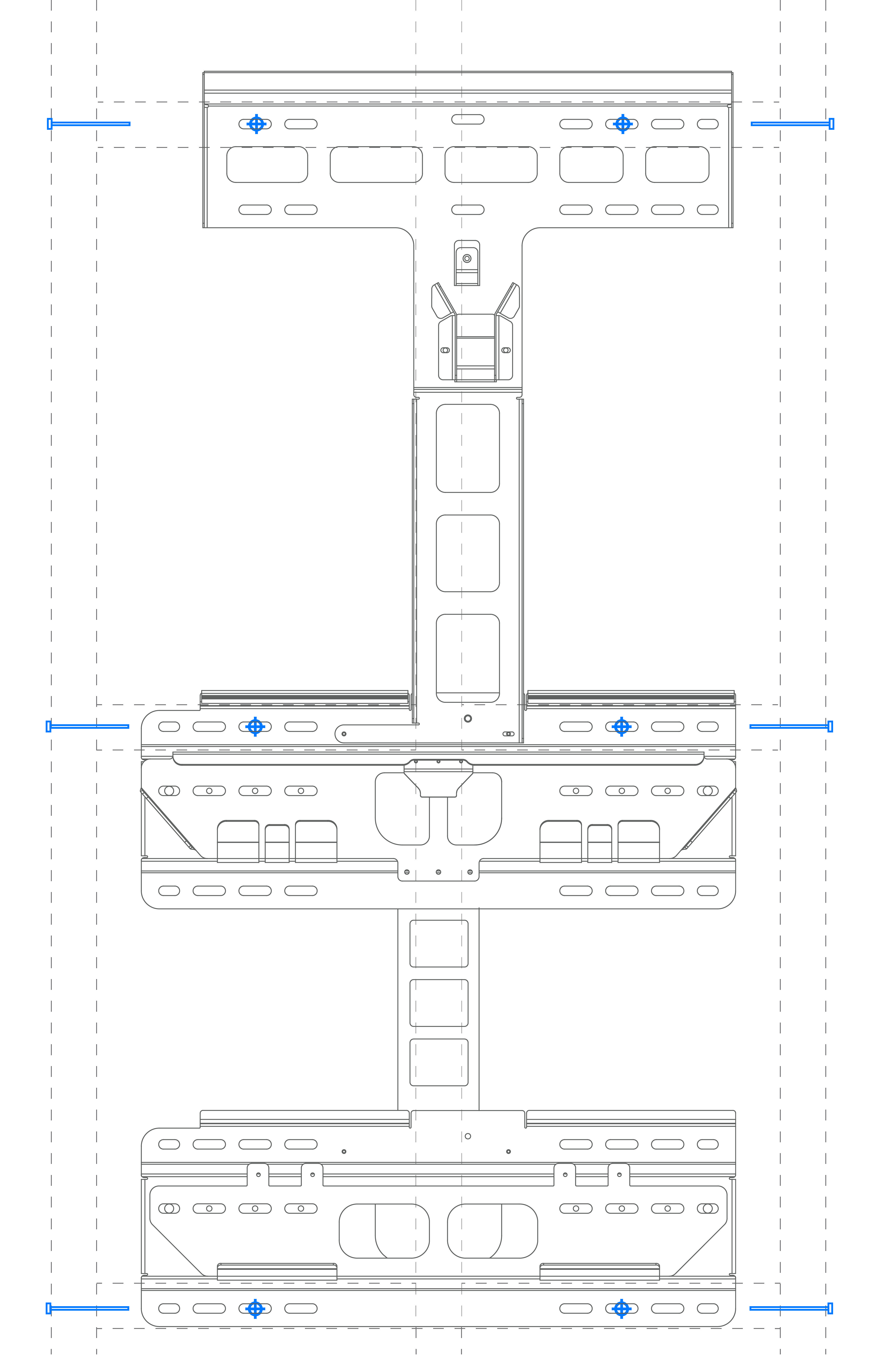

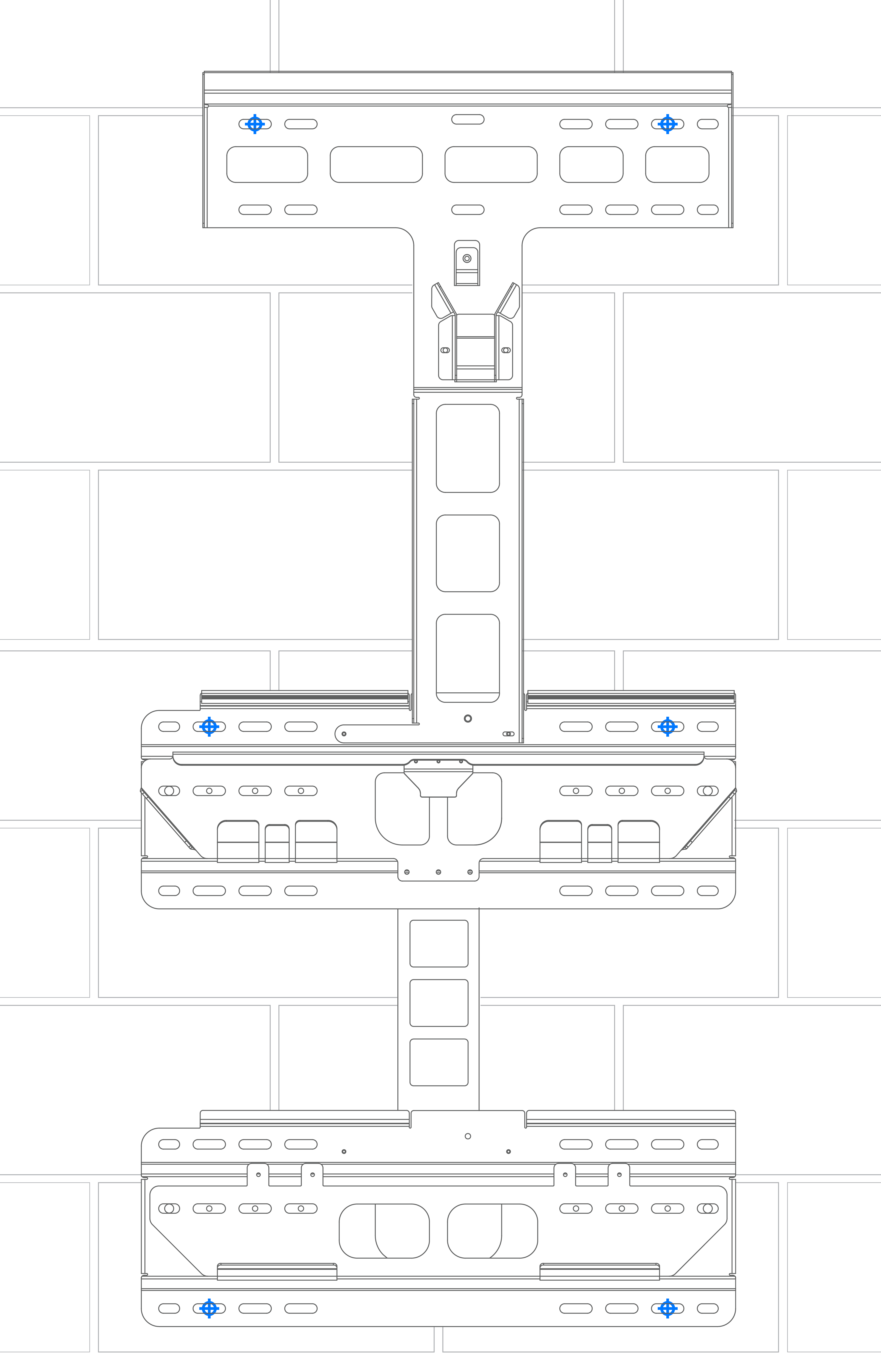

Mounting Bracket Anchoring Details

A2

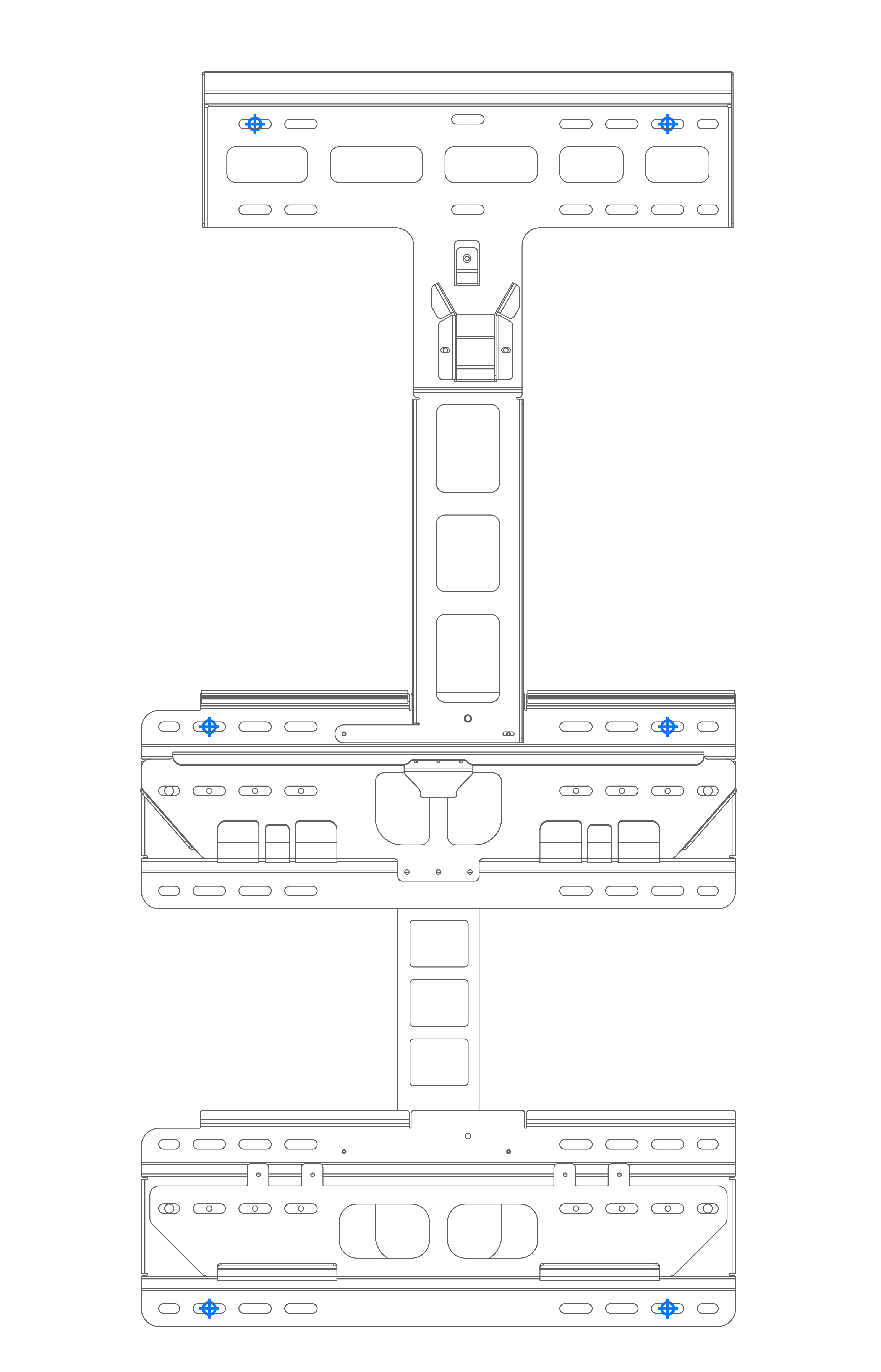

A3 - Mounting Bracket Anchoring Details

A4 - Mounting Bracket Anchoring Details

|

Metal Studs (spaced at 12, 16, 20 or 24 inches) If anchoring directly to metal studs, studs must be minimum 18 gauge. Use at least ten (two in each corner, as shown in blue in the diagram on the right) #14 sheet metal screws with washers, of sufficient length to penetrate at least 3 threads beyond the stud. Note The solar assembly bracket requires only one anchor on each

side. If backing is needed between the studs, the backing must be minimum 18 gauge. Attach backing to metal studs with 12 gauge 3x3 inch angle clip or Simpson SFC2.25 clips with two #10 sheet metal screws in each leg. |

|

|

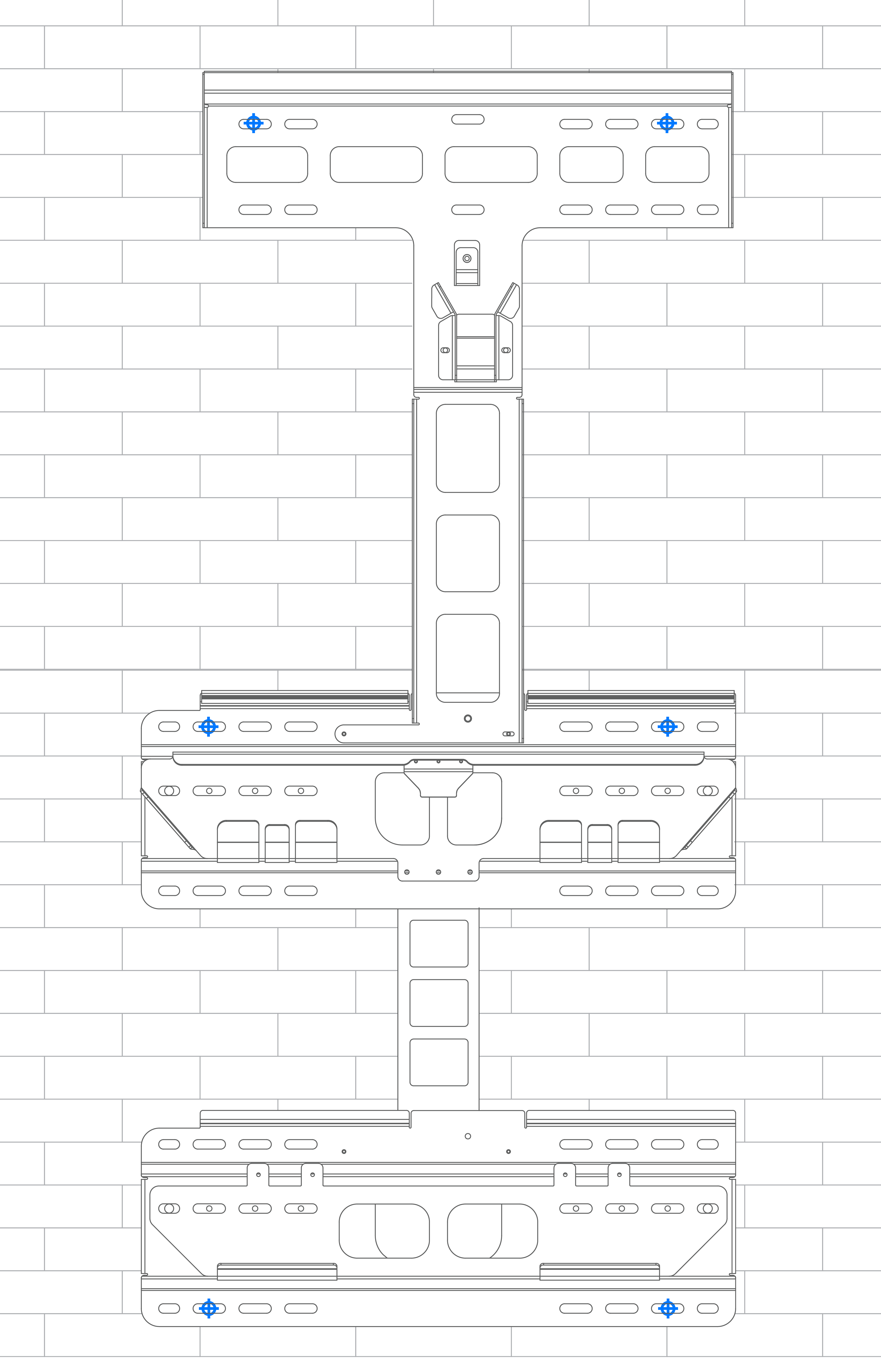

Concrete Masonry Unit Wall Minimum strength must be 2000 PSI. Use at least six (one in each corner, in any available anchor slot) 3/8 inch concrete anchors of sufficient length for the embedment listed below.

Anchors shall not be installed within 12 inches (305 mm) of wall edges or 1-½ inches (38 mm) of masonry block edges. |

|

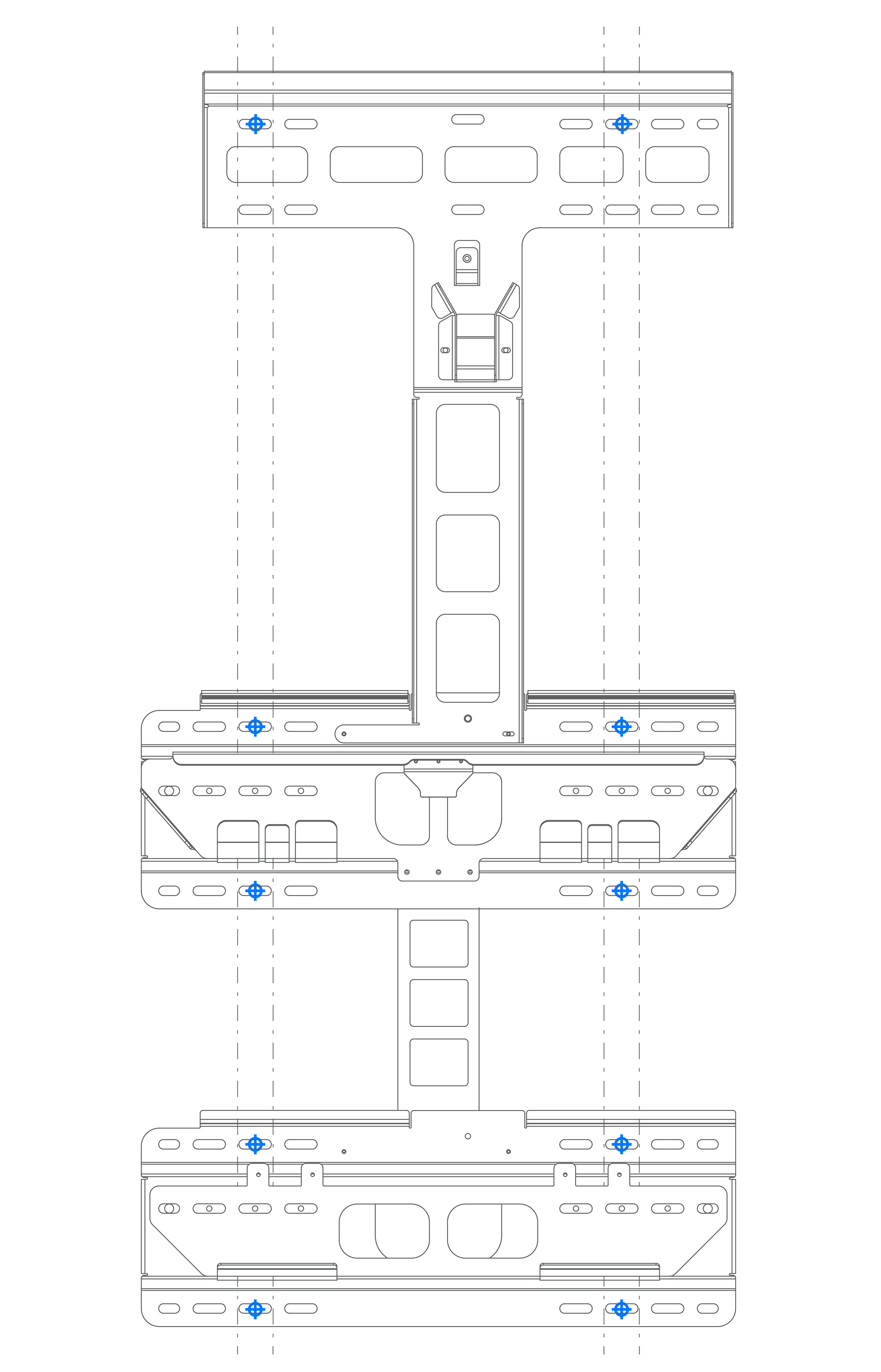

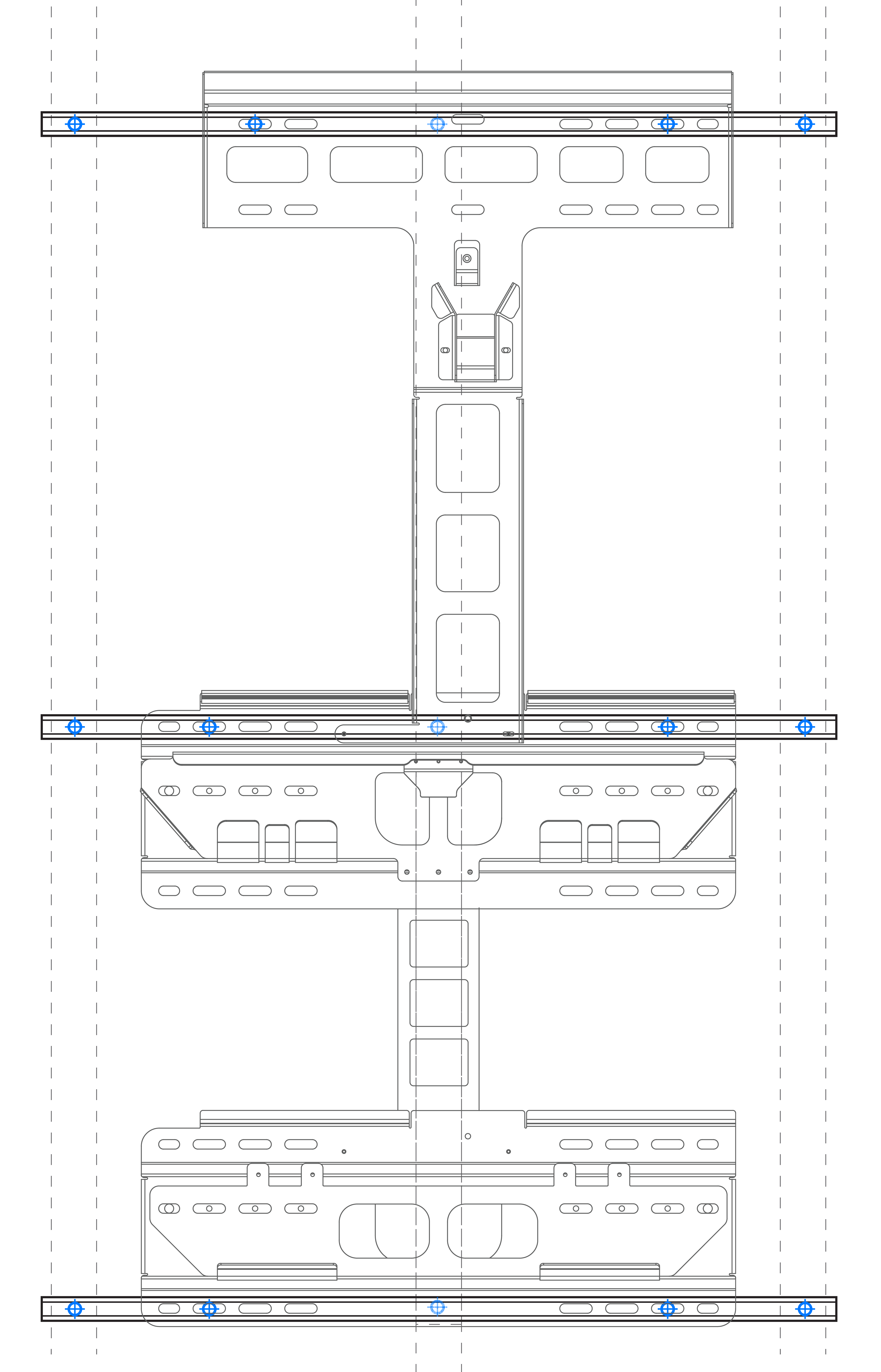

A5 - Mounting Bracket Anchoring Details

A6 - Mounting Bracket Anchoring Details

|

Channel Strut (Unistrut) Struts must be minimum 1-5/8 x 1-5/8 inch, 12 gauge. If mounting on wood studs, attach each strut to at least three studs, using minimum ¼ inch wood screws with washers of sufficient length for at least 2-½ inch embedment into the studs. If mounting on metal studs, attach each strut to at least three studs, using at least one #14 sheet metal screw with washer per stud, of sufficient length to penetrate at least 3 threads beyond the studs. To attach the bracket to the struts, use at least six (one in each corner, as shown in blue in the diagram on the right) ¼ inch hex head screws with washers and strut nuts. Channel strut shall have a maximum unsupported span of 24 inches (610 mm) and shall not be cantilevered. |

|