Field-Made MC4 Quick Guide

Overview

This section outlines best practices for creating MC4 connections in the field when needed. Click here to access the full training module for this procedure.

Tools & Equipment

- MC4 connector tool

- Crimping tool

- Torque tool

- Cut-resistant gloves

Pictured:

Work Instruction

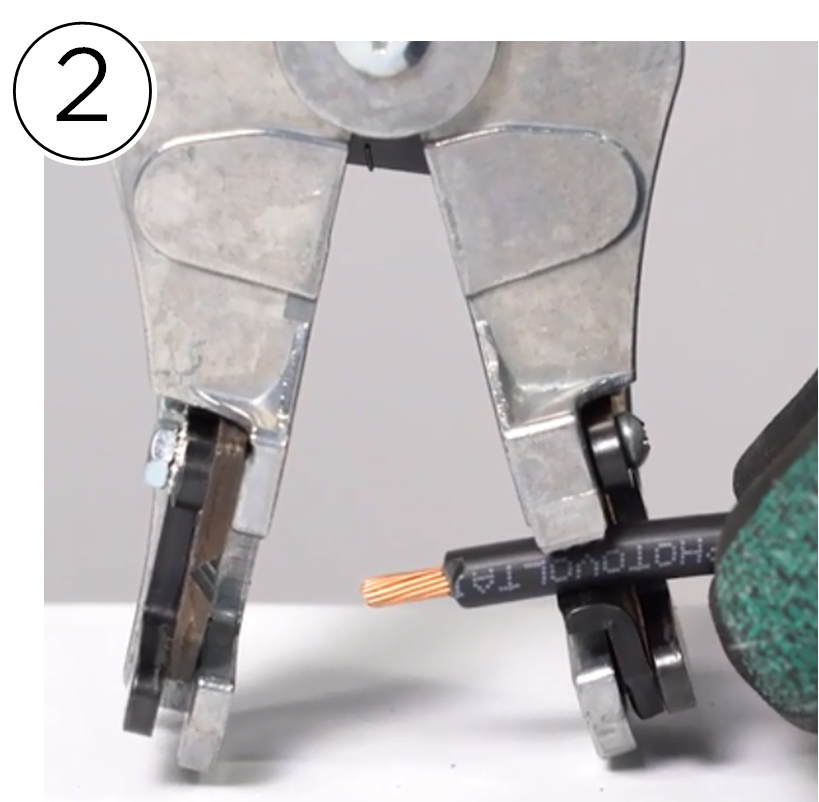

Cut wires at a perpendicular angle (1). Strip wires within the manufacturer's provided tolerance (2).

Crimp the correct pin or socket in accordance with the crimping tool manufacturer's

instructions (4).

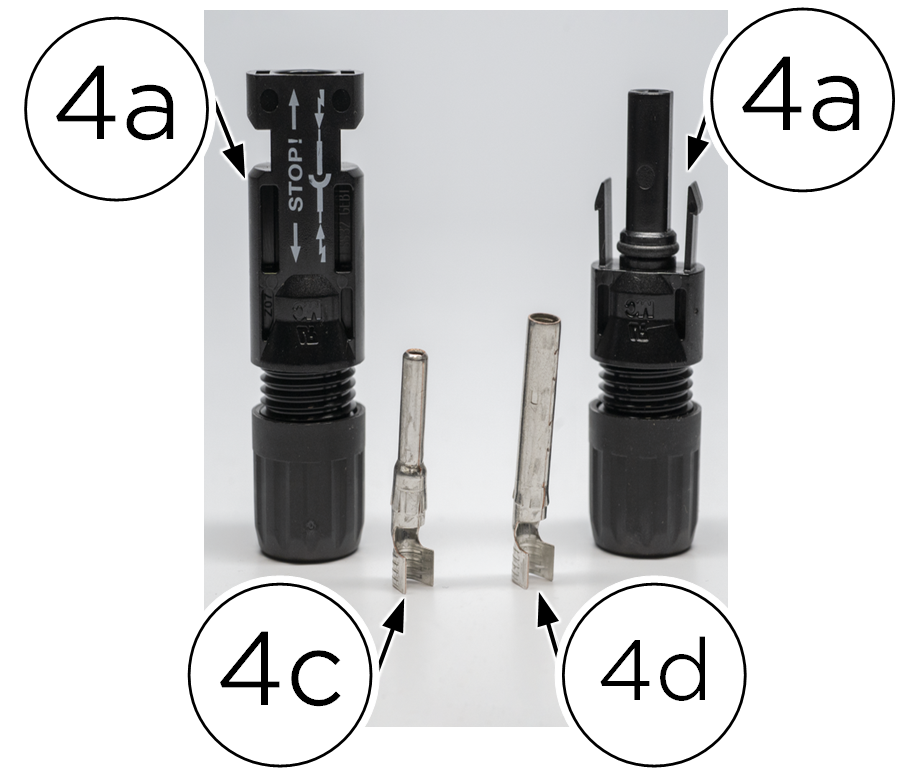

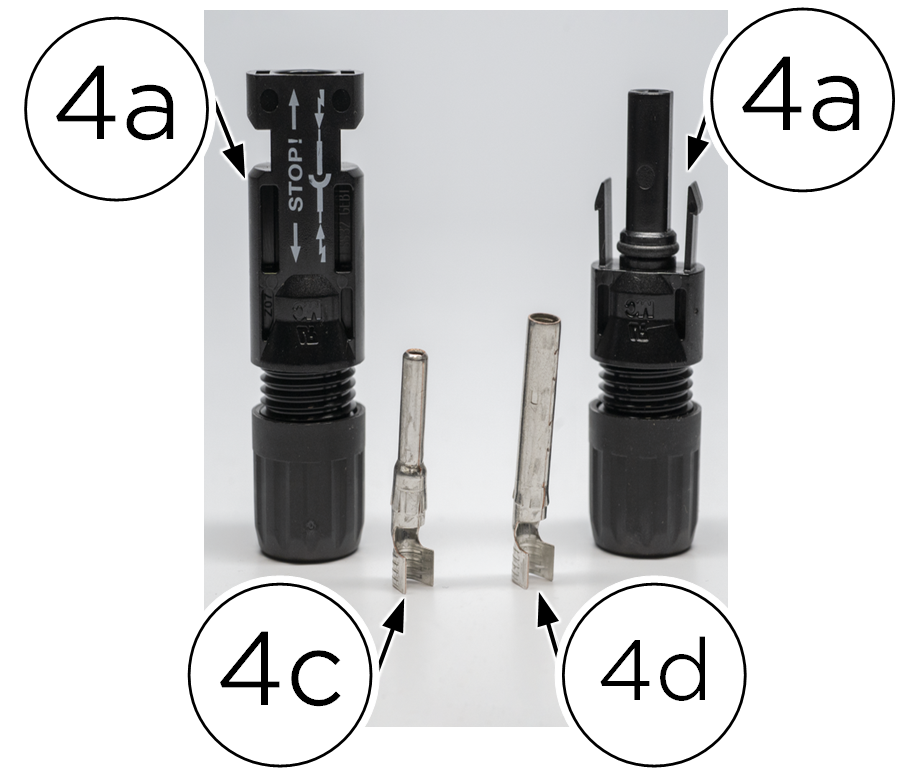

Pictured:

Female

Housing (4a), Male Housing (4b), Female Socket Terminal

(4c), Male Pin Terminal (4d).

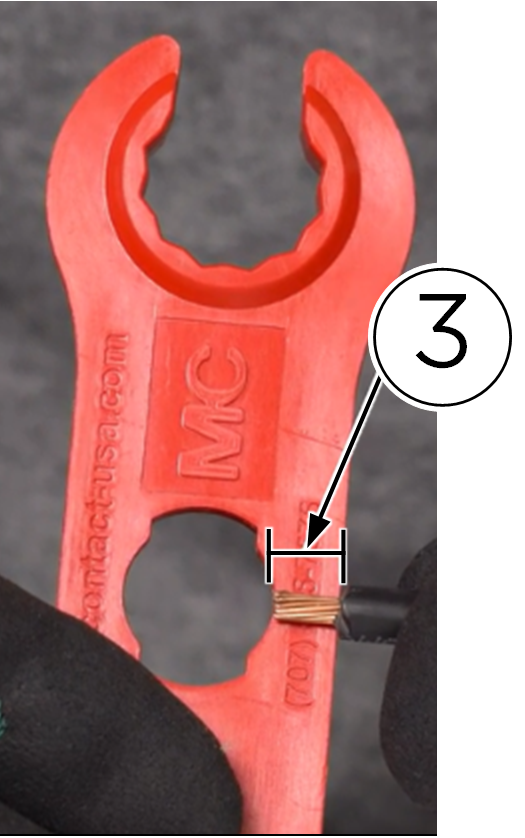

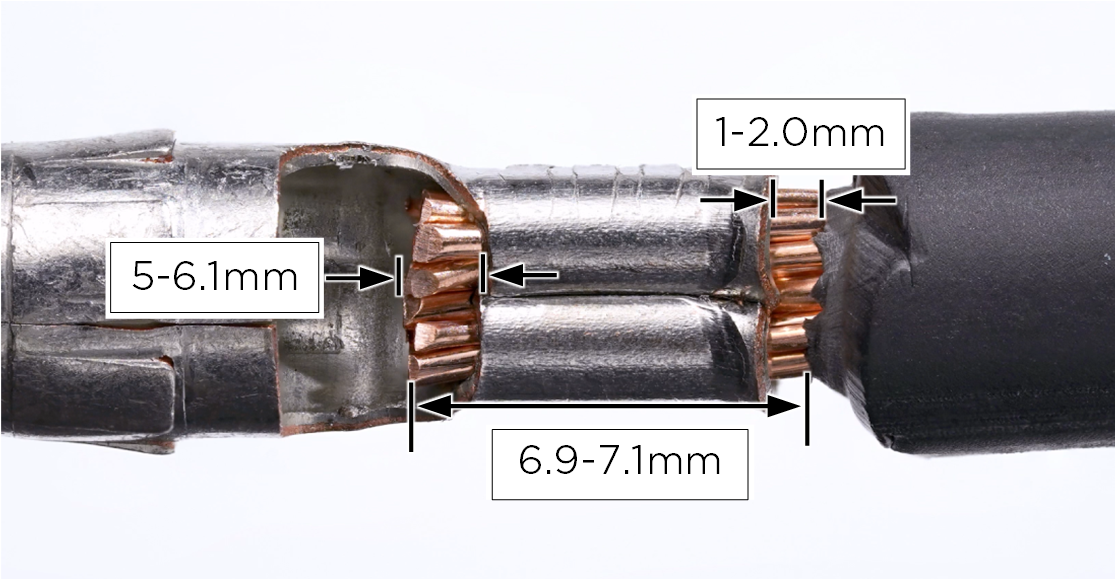

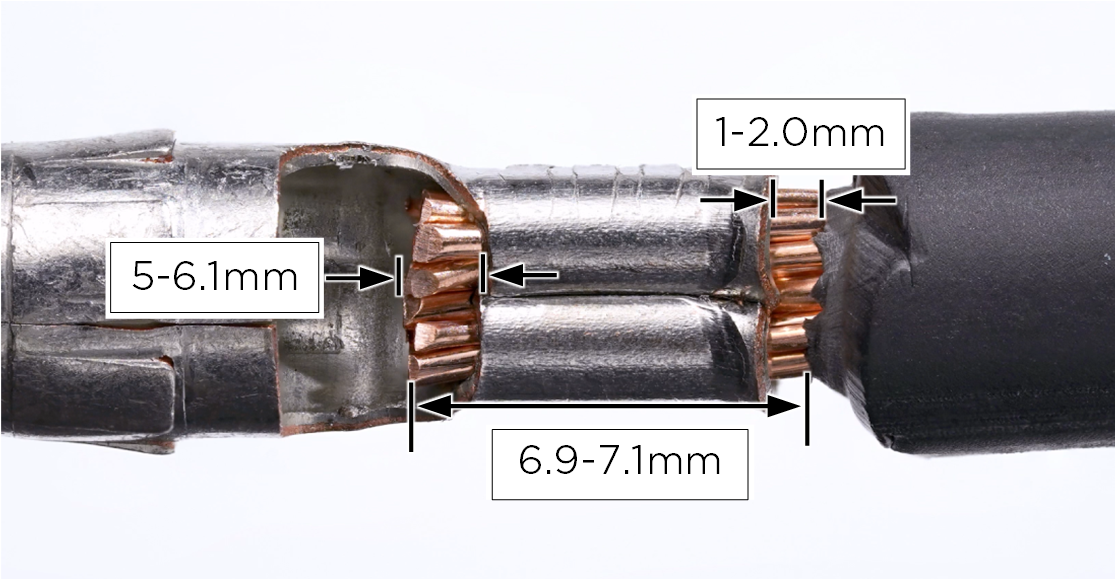

Pictured:

Example of

a correct crimp. Dimensions are in accordance with example manufacturer guidelines:

- Brush: 5-1.5-millimeters

- Gap: 1-2.0 millimeters

- Strip length: 6.9-7.1-millimeters

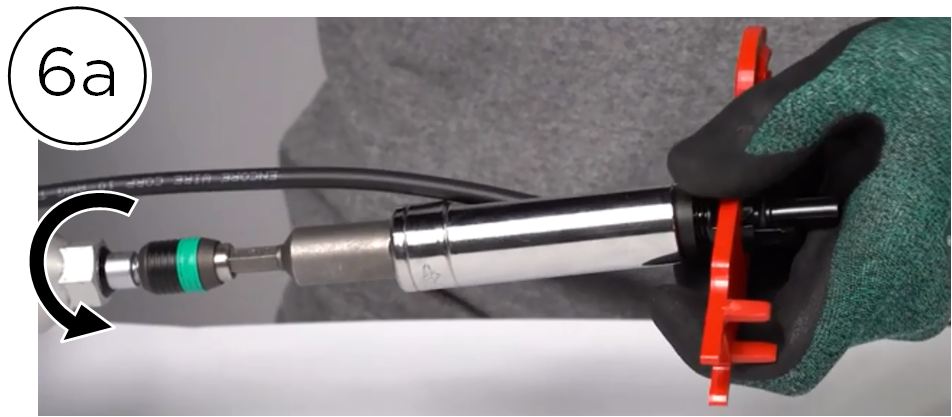

Tighten the backing nut with a torque tool (6).