STEP 3: Install Mechanical Tubing

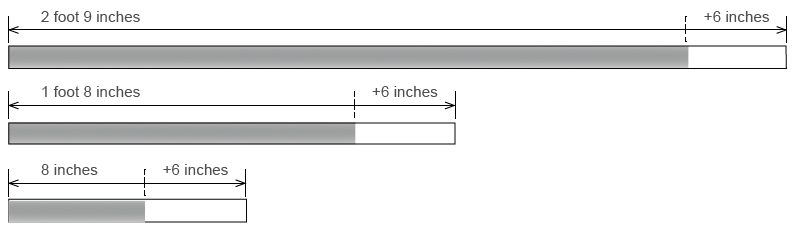

- Cut tubing to length.

-

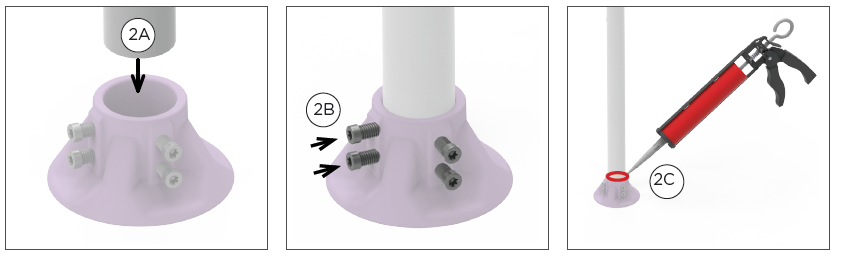

Mount to base

feet.

Insert the Mechanical Tubing into the Base Feet (2A) and fasten the Base Feet Set Screws (2B). Apply sealant between the Base Foot and Mechanical Tubing (2C). Refer to the Approved Sealants section for a list of approved sealants.

-

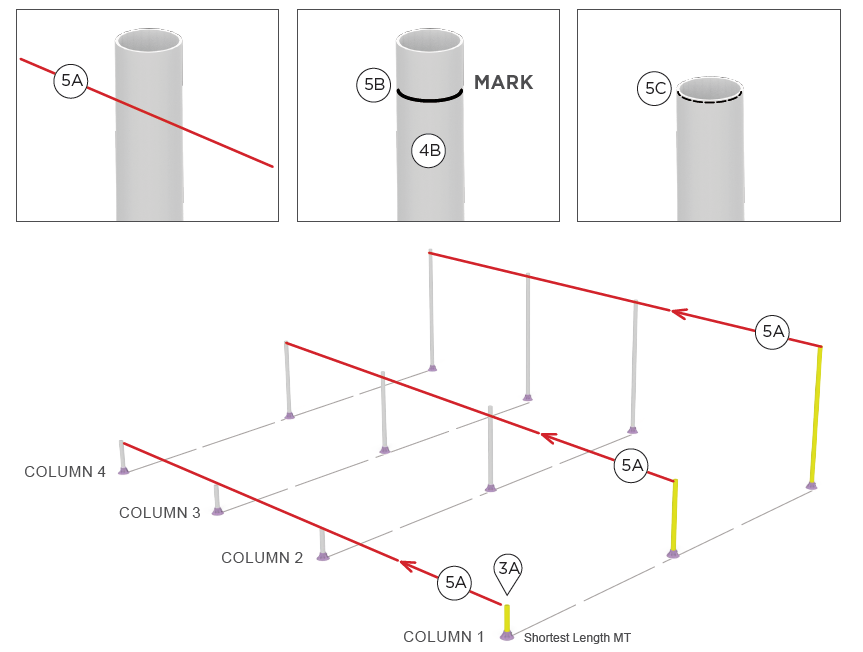

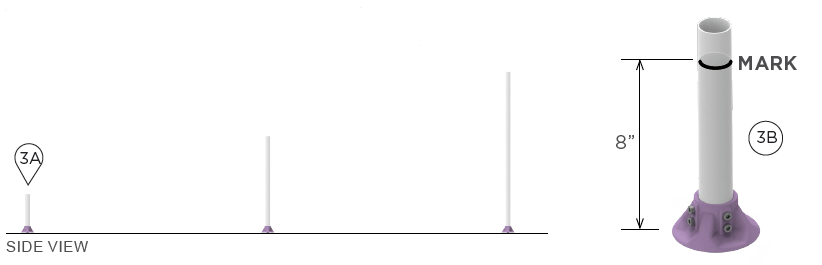

Mark height of shortest length mechanical tubing.

Select the starting Mechanical Tubing (3A), which will be a short-length Mechanical Tubing at the highest elevation on the roof. Use a Measuring Tape to measure out the height specified in project plan set (3B). In case of uneven roof surfaces, begin with the short-length MT at the highest point on the roof.

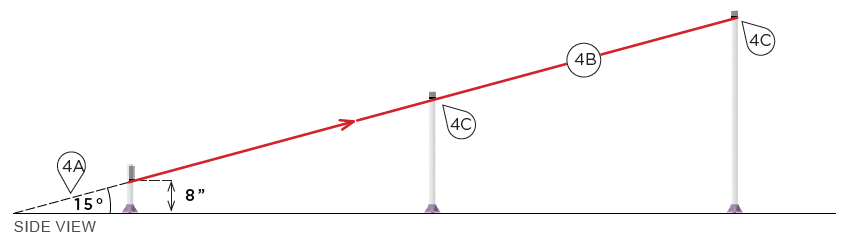

- Measure and mark the slope of the first column.

- Match other columns.